TM 5-4320-218-15

c. Installation.

(2) Take up on the locknut at the end of

(1) Place the two pieces of felt (9) in

the adjusting rod (9, fig. 14) until the

position and lower the fuel tank (8)

spring (8) is horizontal to the engine.

in the same position it was in before

(3) Remove the nut (4) and lockwasher

removal,

from the ball joint on the governor

(2) Place the other two pieces of felt (13)

control rod (6). Push the rod toward

around the fuel tank and place the

the carburetor to open the throttle

two straps (4) in position.

valve. Adjust the positions of the ball

(3) Secure each strap in place with the at-

joints on the control rod until the stud

taching parts.

of the ball joint is aligned with the

(4) Install the strainer and the fuel tank

top hole in the governor lever (7).

Install the nut (4) and lockwasher

cap with its gasket and install the fuel

lines as instructed in paragraph 55c.

to secure the ball joint to the governor

lever.

(5) Close drain cock (12) in bottom of

c. Removal.

tank.

(1) Remove the nut (4, fig. 14), and pull

(6) Tighten each fitting and fill the fuel

the governor control rod (6) out of

tank and check for leaks.

the governor lever (7).

57. Governor

(2) Disconnect the governor spring (8)

from the governor lever.

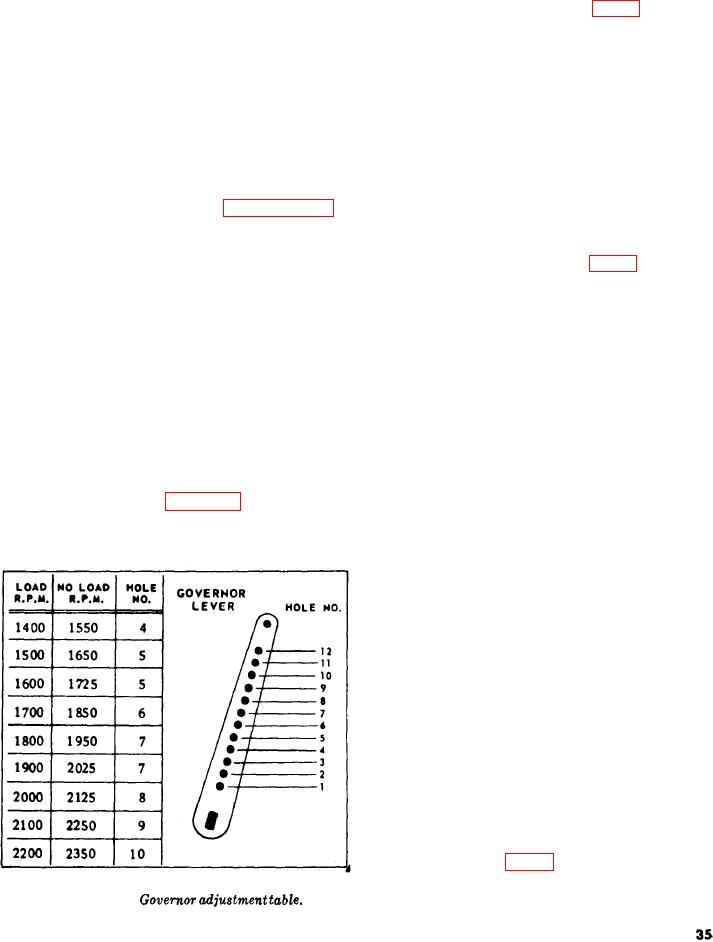

a. General. The engine governor is of the

(3) Disconnect the oil line (10) from the

centrifugal fly-weight type, is driven by the

pipe nipple on the governor. Discon-

camshaft gear, and functions to maintain a con-

nect the tachometer adapter (12) from

stant engine speed under varying load condi-

governor.

tions. The governed engine speed can be ad-

(4) Remove the four cap screws (2) and

justed by fitting the governor spring to one of

lockwashers (3) that secure the gov-

the 12 holes in the governor lever.

ernor housing (1) to the gear cover

b. Adjustment.

(5); remove the governor and its

(1) Determine the desired engine speed,

gasket.

and refer to figure 13 for the proper

(5) Unscrew the pipe nipple (13) from

spring hole in the governor lever; in-

the governor housing.

sert the spring into the proper hole.

d. Cleaning and inspection.

(1) Clean the governor housing and re-

move fittings with an approved clean-

ing solvent; dry thoroughly.

(2) Inspect the governor drive gear for

broken or chipped teeth; replace the

governor if necessary.

(3 Inspect the governor control rod and

adjusting rod for good condition. Re-

place them if they are bent or other-

wise unserviceable.

(4) Inspect the governor housing for

cracks or breaks; replace a damaged

governor, or report the condition to

the proper authority.

(5) Inspect the removed fitting for good

threads. Replace any damaged fitting.

e. Installation (fig. 14).

(1) Install the pipe nipple (13) into the

governor housing.

Figure 13.