TM 5-4320-218-15

a. Install a battery-powered radio receiver in

wiring and units causing interference. This

good operating condition not more than 10 feet,

shielding does not reduce the intensity of the

from the pump. A wide band receiver cov-

interfering surges, but prevents broadcasting.

ering the frequency ragnge of 0.55 to 156.0

Woven metal conduit is used where flexibility

megacycles is preferred.

is required, while solid conduit is used else-

where.

b. Start the equipment and turn on the re-

ceiver. Turn the receiver volume to maximum

49. Effects of Suppression

and select three widely separated frequencies

There is no interference from equipment sat-

for listening. Use frequencies that are free

isfactorily suppressed for broadcasted interfer-

from signals with strong carriers so that the

ence over the frequency range of 0.55 through

receiver will be in its most sensitive operating

156.0 50. megacycles at a distance of 25 feet

condition.

from the unit.

c. Systematically replace suppression compo-

50. Suppression System Testing

nents in the circuit causing trouble, testing af-

ter the replacement of each component to see if

This testing is performed by 3d echelon or

the trouble has been eliminated.

higher.

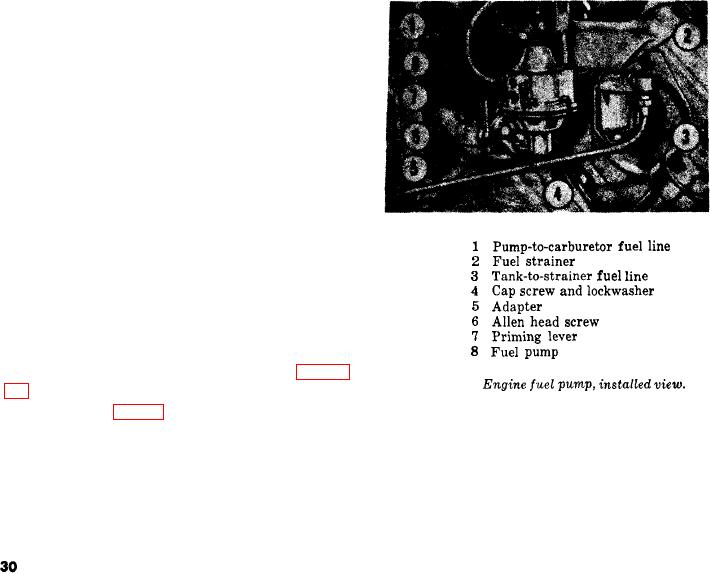

Section VI. ENGINE FUEL SYSTEM

51. Description

The engine fuel system consists of a fuel

tank, fuel pump, fuel strainer, fuel-pump adapt-

er, and hand primer, carburetor, governor, air

cleaner, and fuel lines and connections. Fuel is

drawn from the tank to the strainer, which re-

moves solids and water from the fuel. The

strained fuel passes through the fuel pump and

into the carburetor. The oil-bath air cleaner re-

moves any dust, water, or foreign matter from

the air, and passes clean air to the carburetor

to be mixed with the fuel for proper combus-

tion.

52. Air Cleaner

a. General. The air cleaner is of the oil-bath

type. Air enters the cleaner through the top,

then passes over the oil in the cup and through

the body screen, where any solids or water pres-

ent are left behind. The filtered air then passes

through the air pipe to the carburetor, Figure

Figure 9.

10 shows an exploded view of the air cleaner.

b. Removal (fig. 10),

move the hose (4) from the air

(1) Loosen the screw in the hose clamp (1)

cleaner.

at the carburetor; remove the elbow

(3) Remove the four cap screws (12), lock-

(2) from the carburetor and lift off

washers (11), and hex nuts (10) se-

the spacer,

curing the mounting strap (13) to the

(2) Loosen the screw in the hose clamp

front engine panel; remove the assem-

(1) at the air-cleaner body (6); re-

bled air cleaner and mounting bracket.