TM 10-4320-307-24

3-5

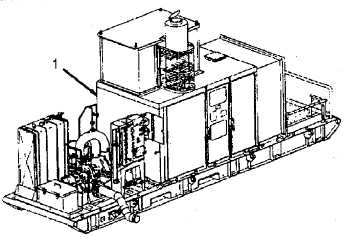

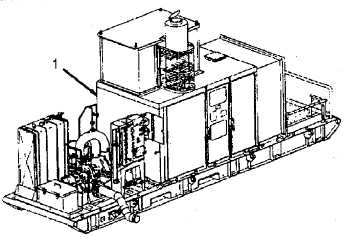

ENGINE ENCLOSURE REPAIR (CONT).

1.

Clean engine enclosure (1) with wire brush and rag

moistened with dry cleaning solvent to remove all

traces of grease and oil. Dry with compressed air.

2.

Inspect engine enclosure (1) for rust spots, dents,

cracks, and gouges.

3.

Inspect all mounting holes for distortion and tearing.

4.

Inspect all latches and handles for proper operation.

5.

Check frame for cracked welds.

6.

Straighten out dents as necessary.

Welding operations produce heat, highly toxic fumes, injurious radiation, metal slag, and

airborne particles. Welding goggles, properly tinted lenses, an apron or jacket, and

welders' boots are required to avoid injury to personnel.

7.

Weld cracks, punctures, or tears in sheet metal, using patches on areas which are rusted through. Repair any

cracked welds in frame. Refer to TM 9-237.

Grinding operations create airborne abrasive dust and particles. Respiratory and eye protection is

required to avoid injury to personnel.

8.

Grind smooth any gouges.

9.

Use emery cloth to smooth out repaired areas and repaint.

10. Replace engine enclosure in accordance with paragraph 2-23.

3-8