TM 5-4320-300-14

6-11. CRANKSHAFT AND FLYWHEEL (CONT)

Location/Item

Action

Remarks

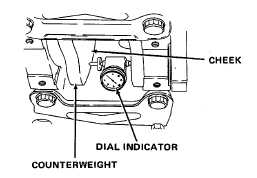

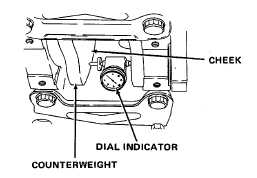

63. Crankshaft

Rotate crankshaft clockwise

counterweight

until crankshaft counter-

check

weights at rear connecting

rod journal are in the

6 o'clock position. Center

punch a hole in the inside

face of each counterweight

cheek, 1/4 inch (6.35 mm)

from lower end of each

counterweight. Install a

dial gage in center punch

holes in cheek of each

counterweight. Set dial in-

dicator at zero. Rotate the

crankshaft to the 3 and 9 o'clock positions.

Note indicator readings at the 3, 6, and

9 o'clock counterweight positions. The maxi-

mum allowable variation is 0.0045 inch

(0.1143 mm) total indicator reading.

CAUTION

Equipment damage due to crankshaft distortion may occur if flexible coupling is misaligned

during installation. Install coupling on engine carefully.

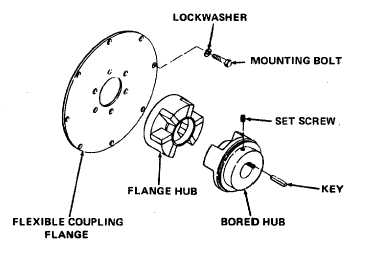

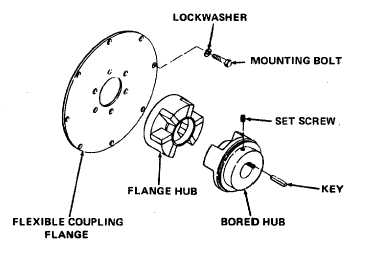

64. Flexible

Position flange, flange hub, bored hub, set

coupling

screw, and key as a unit against the flywheel.

Install flange mounting bolts and lockwashers.

Tighten bolts securely.

6-114