TM 5-4320-300-14

6-12. BEARINGS (CONT)

Location/Item

Action

Remarks

b. Rotate crankshaft about 30 degrees from

bottom dead center; then install lower

bearing shells and caps.

NOTE

Bolts will seat better if bolt caps are rapped sharply with a soft hammer after being installed hand

tight.

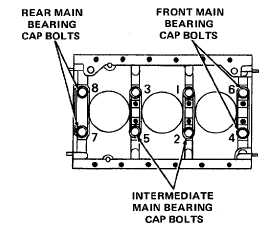

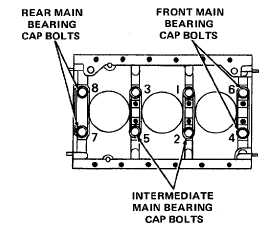

c. Torque front and intermediate main bear-

ing cap bolts to 120 to 130 ft lb (163 to

176 N.m), in an alternating pattern as

shown.

d. Torque rear main bearing cap bolts to 40 to

50 foot pounds (54 to 68 N.m).

e. Remove all bearing cap bolts and caps. Use

lifting device to remove crankshaft, and re-

move the flattened plastic strip.

f. Compare width of flattened plastic strip at

its widest point with graduations on envelope

gage to determine clearance encountered. The

number within the graduation on the envelope

indicates bearing clearance in thousandths of

an inch.

9.

Clearance

The clearance between a crankshaft journal and

limits

its bearing shell should be not greater than 0.006

inch (0.1524 mm). Replace all bearing shells if

any must be replaced.

6-118