TM 5-4320-300-14

6-12. BEARINGS (CONT)

Location/Item

Action

Remarks

CLEANING OF

BEARING SHELLS

WARNING

Severe burns, illness, or death may result if personnel fail to handle diesel fuel properly. Observe

the following precautions:

* Do not inhale vapor.

* Work in a well-ventilated area.

* Do not use near open flame, sparks, or excessive heat.

Compressed air used for cleaning shall not exceed 100 psi (690 kPa). Use goggles or face shield

for eye protection. Do not direct airstream against skin.

3.

All main

Wash in clean VV-F-800 diesel fuel and dry with

bearing shells

compressed air.

INSPECTION OF

BEARING SHELLS

4.

Bearing shells

Inspect for scoring, pitting, flaking, etching, loss

Bright spots indi-

of babbit, signs of overheating, and bright spots

cate that shells

on backs of shells. Replace bearings that are

have been moving

damaged, show excessive wear, or have bright

in caps.

spots.

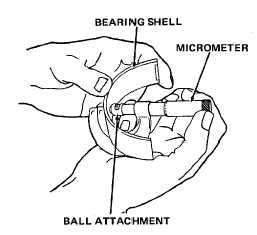

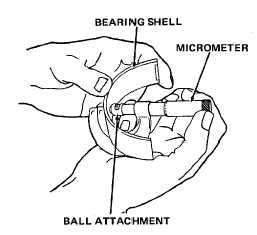

5.

Bearing shell

If bearing shells are free of

thickness

excessive wear, bright spots,

and damage, measure shell

thickness. Shells should not

be less than 0.1230 inch

(3.1242 mm) thick. If any

bearing shell measures less

than 0.1230 inch (3.1242

mm), replace all bearing

shells.

6.

Bearing shell

Position upper main bearing shells in bearing

and crankshaft

supports. Lubricate crankshaft main bearing

journal prepa-

journals with MI L-L-2104 oil.

ration

6-116