TM 5-4320-300-14

6-11. CRANKSHAFT AND FLYWHEEL (CONT)

Location/Item

Action

Remarks

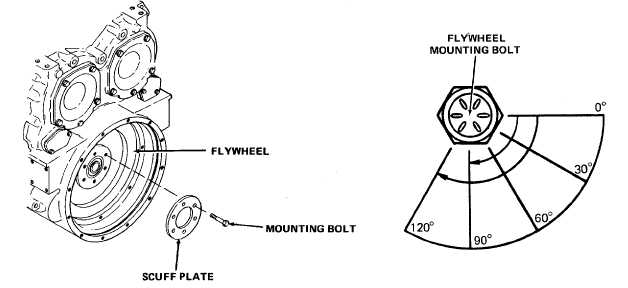

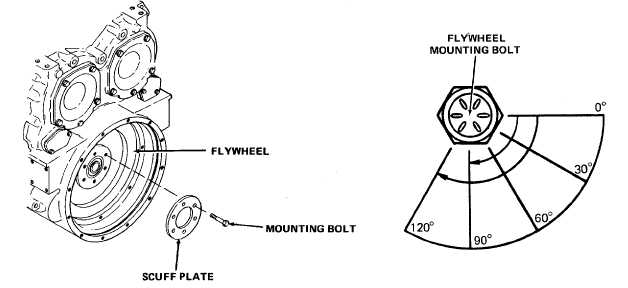

59. Scuff plate

Thread two mounting bolts (across from each other)

through scuff plate and into flywheel and crankshaft.

Tighten bolts hand tight. Remove guide studs. Apply

MIL-T-22361 thread compound to threads and to bolt

head contact areas of remaining bolts. Wipe off excess

thread compound. Thread bolts in and tighten hand

tight. Remove bolts used as temporary flywheel re-

tainers, coat threads with thread compound and rein-

stall fingertight. Torque all bolts in an opposite (across

from each other) pattern to 50 ft lb (68 N.m). Turn

bolts an additional 90 to 120 degrees to obtain clamping.

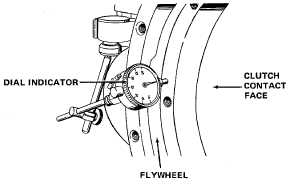

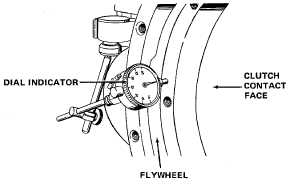

60. Flywheel

Mount a dial indicator on the flywheel

The radius is measured

runout check

housing. Check flywheel runout at the

from center of fly-

clutch contact face. The maximum allow-

wheel to outer edge of

able runout is 0.001 inch (0.0254 mm)

clutch contact surface.

indicator reading per

inch of radius. If

runout exceeds limits,

remove flywheel and

clean flywheel-to-

crankshaft mating

area. Reinstall fly-

wheel and torque

bolts. Clamp bolts

accurately. Recheck

runout. If runout

exceeds limits, re-

place flywheel.

6-112