c .

d.

e .

f .

g.

h.

i .

TM 10-4320-344-24

If insert (2) does not come out of tapped hole, go to step d.

I f i n s e r t ( 2 )

does come out of tapped hole, go to step h.

Insert scribe (3) between end of insert (2) and tapped hole.

Work end of insert (2) away from tapped hole and form a tang

to diameter of insert (2).

Using needle nose pliers (4), grasp tang.

equal in length

Turn insert (2) counterclockwise until insert is out of tapped hole.

Discard

i n s e r t ( 2 ).

Lubricate finishing tap (5) with transmission oil.

Using finishing tap (5) and tap handle, slowly thread tap in and out of tapped

h o l e.

Compressed air can blow dust into the eyes.

Wear eye protection.

Do not

exceed 30 psi (207 kPa) air pressure.

Dry cleaning solvent is highly toxic and can ignite

organic materials, nitrates, carbides, and chlorates.

Wear eye, skin, and

respiratory protection.

Use only in well ventilated area.

j .

Using compressed air, blow out dirt and any loose metal chips in tapped hole.

k.

Use wiping rag dampened with cleaning solvent to clean tapped hole.

l .

If threads can not be restored or excessive damage exists, go to 2.11.2.5. If

threads are not damaged, go to 2.11.2.6.

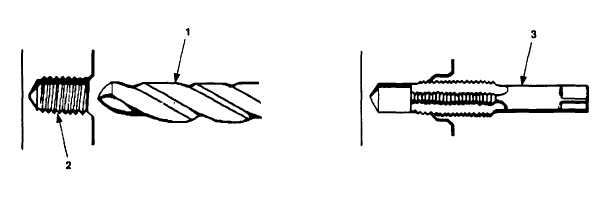

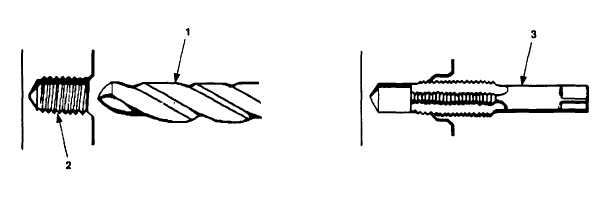

2.11.2.5

Oversizing Insert Pilot Holes. (Refer to figure 2-8)

Figure 2-8.

Oversizing Insert Pilot Holes.

A l l s i z e s f or

to repair kit

a.

Using drill

tools and threaded inserts depend on original bolt size.

Refer

for proper drill and tap sizes.

(Figure 2-8, 1) bore out damaged threads (2) to original depth.

2-41