TM 10-4320-344-24

2.11.2 Stud and Thread Repair. (Continued)

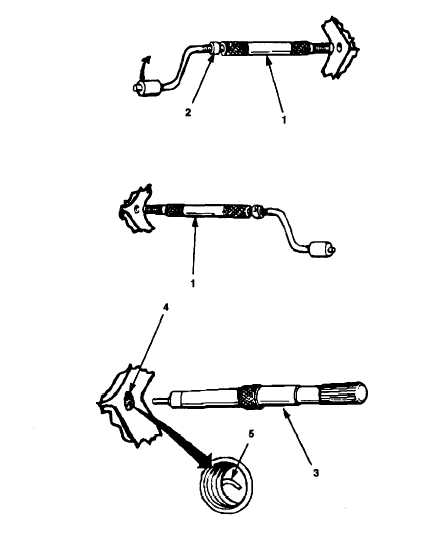

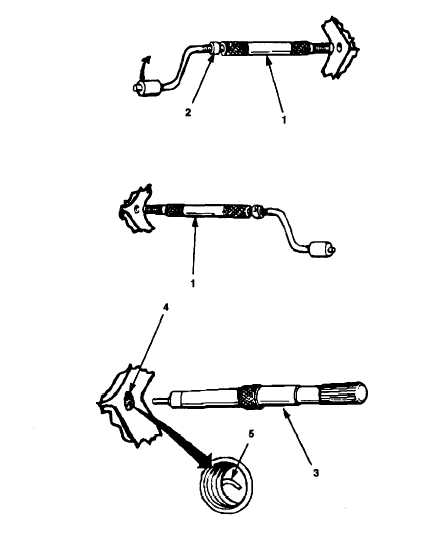

Figure 2-10.

Installing Threaded Insert.

Insertion tool must be straight and not allowed to wobble when installing

i n s e r t.

Equipment can be damaged.

Do not force insert into tapped hole.

Threads will be damaged.

k.

Put tip of insertion tool (Figure 2-10,

1) against tapped hole being sure that

i n s e r t i o n t o o l i s s t r a i g h t .

l .

Slowly turn handle of insertion tool (1) clockwise until stop collar (2)

c o n t a c t s b o d y o f i n s e r t i o n t o o l ( 1 ).

m.

Turn handle of insertion tool (1) counterclockwise until insertion tool (1)

can be removed.

n.

Place tang breakoff tool (3) in tapped hole with threaded insert (4).

o .

Push down end of breakoff tool (3) until tang (5) breaks off insert.

2-44