TM 10-4320-344-24

2.11.2 Stud and Thread Repair.

This task covers:

Repair

INITIAL SETUP

Use With

Material/Parts

Trailer-Mounted Pump Assemblies

Gloves, Appendix C, Item 11

609-A, 609-C and US636HCCD-1

Oil, General Lubricating, Appendix C,

Item 16

Tools

Oil, Transmission, Appendix C, Item 17

Rags, Wiping, Appendix C, Item 20

General Mechanic’s Automotive

Solvent, Dry Cleaning, Appendix C, Item 26

Tool Kit, Appendix B, Section

III, Item 1

Air Blow Gun, Appendix B, Section

Equipment Conditions

III, Item 2

Electric Portable Drill, Appendix

Pumping station shut down, TM

B, Section III, Item 2

10-4320-344-10.

Goggles, Appendix B, Section III,

Item 2

General Safety Instructions

Screw Extractor Set, Appendix B,

Section III, Item 2

To prevent rolling or sliding, do not work

Twist Drill Set, Appendix B,

on equipment that is not securely

Section III, Item 2

s t a b i l i z e d.

Screw Threading Set, Appendix B,

Section III, Item 3

Do not work on equipment without following

standard shop safety precautions.

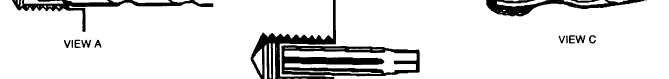

2.11.2.1 Repairing Studs or Screws Broken Flush.

(Refer to Figure 2-6, View A)

a .

Center punch broken stud or screw.

Be careful not to drill into the component when repairing studs or screws.

Failure to obey this caution will result in damage to the equipment.

b.

Drill into broken stud or screw using a drill bit 1/16 inch (0.002 mm) less

than the diameter of the broken stud or screw.

c .

Using a screw extractor, remove broken stud or screw.

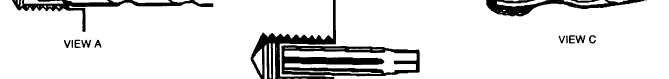

Figure 2-6. Removing or Repairing Studs or Screws.

2-39