TM

10-4320-344-24

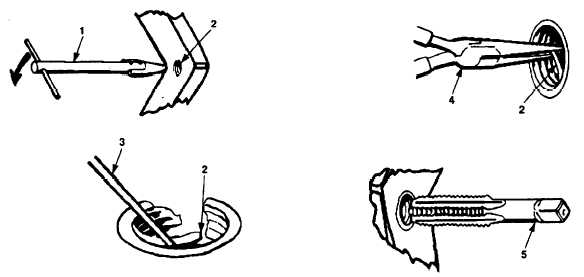

2.11.2 Stud and Thread Repair. (Continued)

2.11.2.2 Removing Studs or Screws That Have Not Broken Flush.

(Refer to Figure 2-6, Views B

and C)

a.

Spray broken stud or screw with general lubricating oil and allow it to

penetrate.

b .

Clamp broken stud or screw using pliers.

c .

Tap broken stud or screw and back out.

d.

If stud or screw can not be removed, repair stud or screw (paragraph

2 .

11 . 2 . 1 ) .

2.11.2.3 Repair Of Damaged Threaded Insert.

a.

Using proper tap and transmission oil, chase insert threads.

b .

If threads can not be restored or excessive damage exists, replace damaged

inserts (paragraph 2.11.2.4).

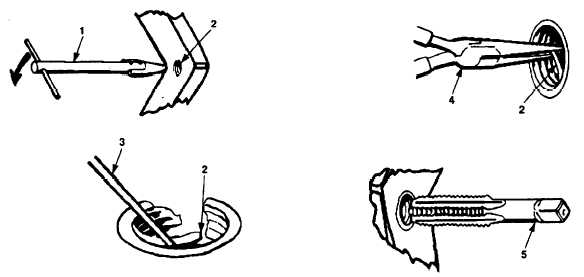

2.11.2.4 Removing Damaged Threaded Insert. (Refer to Figure 2-7)

Figure 2-7. Removing Damaged Threaded Insert.

• Do not damage threads of tapped hole when using extraction tool.

• Remove inserts from end of tapped hole that the insert is closest to.

Threads

in tapped hole can be damaged.

All sizes for tools and threaded inserts depend on original size.

a .

Place extraction tool (Figure 2-7, 1) in insert (2). Tap top of extraction

t o o l ( 1 ).

b .

Maintaining a steady downward pressure, turn extraction tool (1)

counterclockwise and remove insert (2).

2-40