(4)

Recheck the shaft alignment between the

engine and pump.

If all alignment is

correct, position the coupling halves

together and secure with eight bolts (4, fig.

47 and nuts (6).

102. Assembled Engine, Stub Shaft, and Dash

a. Removal.

(1) Remove the eight bolts (4, fig. 43) and nuts

(6) that secure the coupling halves together.

(2) Remove the side panels and top hood from

the engine (para 99).

(3) Remove the eight engine mounting bolts (5,

fig. 45) and lockwashers that secure the

engine to the skid base. A lifting eye is

provided on one of the cylinder head studs

to facilitate hoisting the engine. Remove

the engine from the skid base.

(4) Pull the coupling hub (3, fig. 43) and key

from the stub shaft on the engine and

remove the coupling half (5) with its

assembled seal (2) and retaining ring (1).

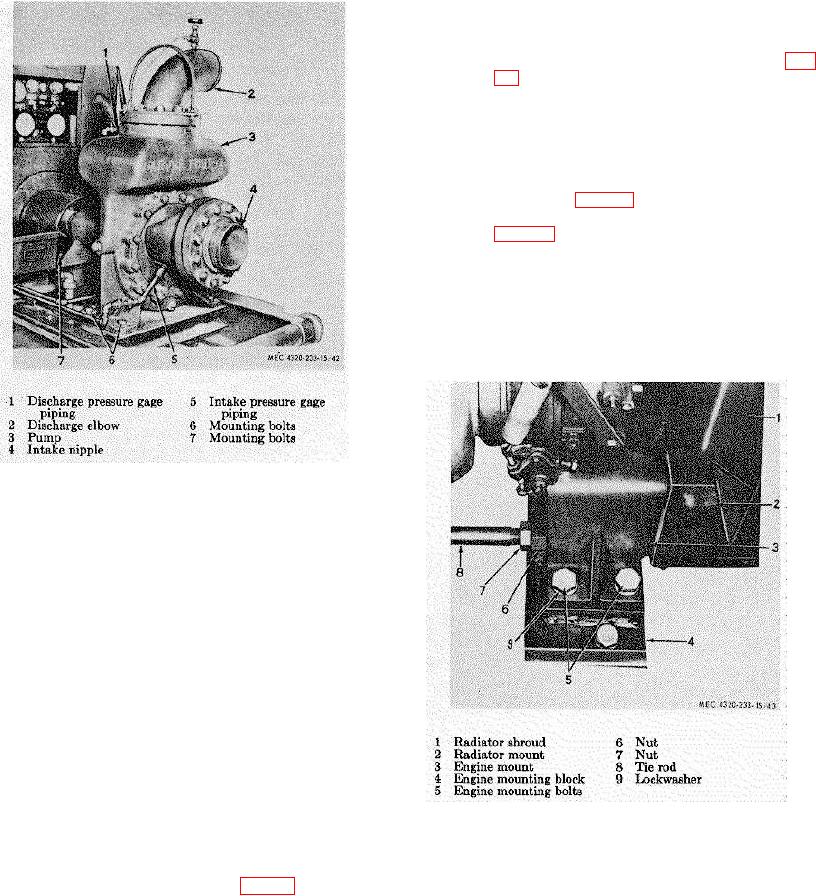

Figure 44. Pump installation.

(4) Remove the coupling hub (3, fig. 43), key,

and coupling half with its assembled seal (2)

and retaining ring (1) from the pump shaft.

b. Cleaning and Inspection.

(1) Clean the outside of the pump with a cloth

dampened with cleaning solvent; wipe dry.

Take care not to let solvent enter the pump.

(2) Inspect the pumpfor cracks, breaks, bent or

scored shaft, or other damage; refer to

higher authority if damaged.

c. Installation.

(1) Position the coupling half (5) with the

assembled seal (2) and retaining ring (1) on

the pump shaft. Position the key in the

keyway of the pump shaft and install the

hub (3) on the shaft.

(2) Position the pump on the skid base. Use a

straightedge to make sure the pump shaft is

Figure 45. Engine mounting.

perfectly aligned with the engine shaft.

Shim under the pump as necessary to

provide correct alignment of the shafts.

(3) Secure the pump to the skid base with six

mounting bolts (6 and 7, fig. 44).

TAGO 6358-A

57