(b) Position a connecting rod in its

piston. Install the piston pin; secure

with the retaining rings (15).

(5)

Slide the piston rings (10, 11, and 12)

squarely into the cylinders in which they

will be used. Check the ring gap with

feeler stock. Ring gap must be within the

following tolerances:

Top ring............... .008 in. to 0.013 in.

0

Middle rings.........0.011 in. to 0.016 in.

Bottom ring..........0.010 in. to 0.020 in.

(6)

If the gap is too small, file the rings to

provide a proper gap.

(7)

Install the piston rings on the piston with a

standard ring expander.

(8)

Assemble

the

remaining

pistons,

connecting rods, and piston rings.

(9)

Install the assembled pistons and connec-

ting rods in the block using a ring

compressor to compress the piston rings.

Lubricate the pistons and cylinder walls

with engine oil before installing the

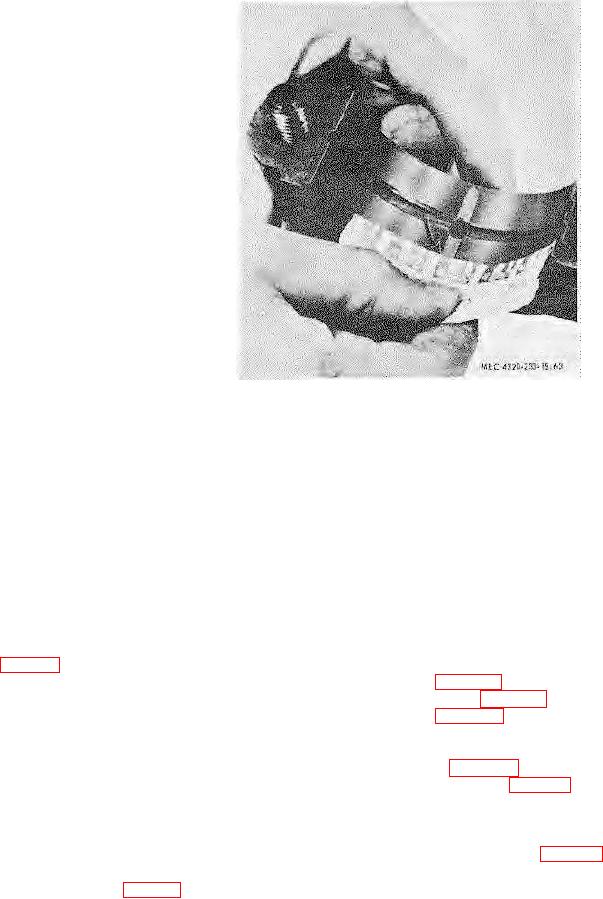

Figure 69. Checking bearing clearance using

pistons. Wrap the bottom end of the

plastigage.

connecting rods with a cloth to prevent

definite drag will be felt. If clearance is

damage to the cylinder walls during

not within tolerance, replace the

installation.

connecting rod bearings and recheck the

(10)

Check the crank pin bearing journal-to-

clearance. If clearance is still not within

connecting rod bearing clearance with

tolerance, replace the crankshaft.

plastigage as follows:

(12) Lubricate the crank pin bearing journals

(a) Place a piece of plastigage near the

and the sleeve bearings with engine oil.

oil hole of the bearing cap.

Install a cap (17) on its connecting rod

(b) Position the cap on the connecting

and on the crank pin bearing journal;

rod and secure with the two nuts

secure with the two bolts (18) and nuts

and lockwashers. Tighten the nuts

(32).

Tighten the nuts to 70 to 75

(32) to 70 to 75 foot ounds torque.

-p

foot-pounds torque. Install the cotter pins

(c) Remove the bearing and bearing

(33).

cap.

Check

the

bearing

(13) Secure the remaining connecting rods to

journal-to-bearing clearance using

the crank pins bearing journals.

plastigage (fig. 63). If clearance is

(14) Install the oil pan (para 117

c).

not between 0.0007 and 0.0025

(15) Install the cylinder head (para 115

c).

inch, replace the connecting rod

(16) Install the engine (para 114

c).

bearings and recheck the clearance.

120. Flywheel and Flywheel Housing

If clearance is still not within

a. Removal.

tolerance, replace the crankshaft.

(1) Remove the engine (para 114).

b

(11)

As an alternate method of checking crank

(2) Remove the six nuts (1, fig. 68) and

pin bearing journalto-connecting rod

-

lockwashers (2) that secure the flywheel

bearing clearance, install a piece of

(3) to the crankshaft (20); remove the

0.0025-inch thick feeler stock between the

flywheel.

bearing and journal.

Lubricate the

(3) Remove the four screws (3, fig. 56),

bearing journal with SAE 10 engine oil.

lockwashers (4), and two nuts (1) that

Install the connecting rod cap. Tighten

secure the flywheel housing (6) to the

the connecting rod cap nuts (32, fig. 68)

block (28); remove the flywheel housing.

to 70 to 75 footpounds torque. Try to

-

slide the connecting rod alternately toward

the front and rear of the engine.

If

clearance is within tolerance, a

TAGO 8368 A

-

80