(3) Check the fit of the idler gear (26) and the

stud (25); press the stud from the pump

body and press in a new stud if the old

one is worn, or if the idler gear has been

rubbing the walls of the chamber.

(4) Examine the screen for enlarged

openings, breaks, or blocked openings;

clean screen openings or replace.

d. Assembly.

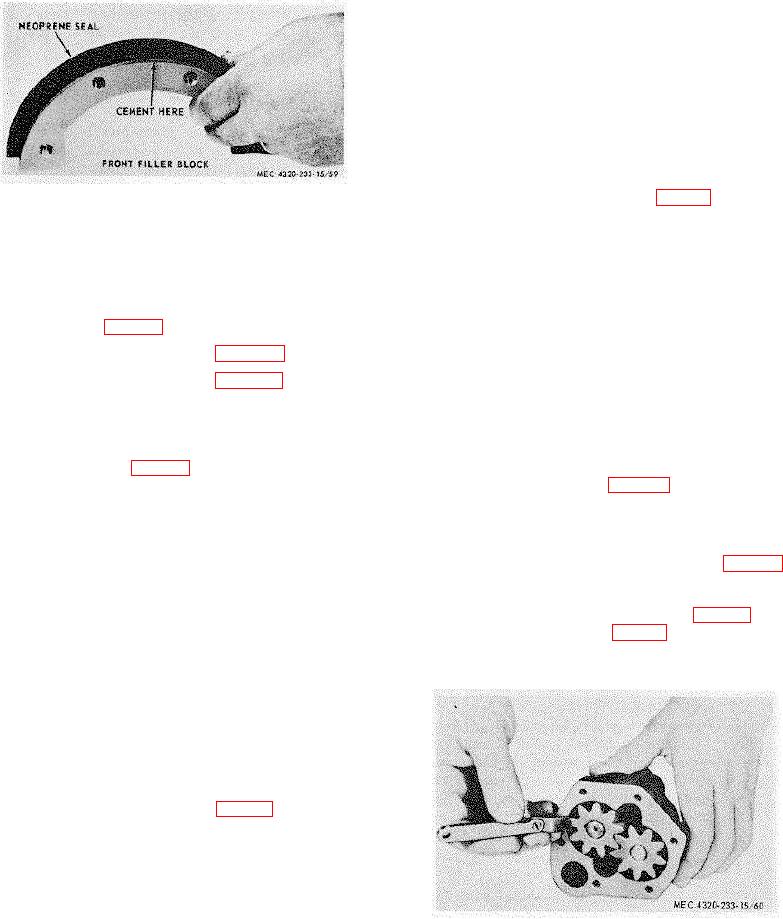

Figure 65. Installing neoprene seal in front filer

(1) Position the key (35, fig. 59) in the slot in

block.

the drive shaft (36). Press the driver gear

(34) on the drive shaft far enough to

lockwashers (63). Tighten the screws to

install the retaining ring (33), install the

12 to 16 footpounds torque.

-

retaining ring and press the gear back

(7) Install the engine (pare 114c).

against the ring.

118. Oil Pump

(2) Place the idler gear (26) in position in the

a. Removal (fig. 59).

pump body (37) and on the stud (25).

(1) Remove the engine (para 114).

b

(3) Install the assembled driver gear and

shaft in the pump body. Press the drive

(2) Remove the oil pan (para 117).

a

gear (40) onto the drive shaft, with the pin

hole the gear in line with the pin hole in

(3) Remove the nut (24) and lockwasher (23)

the shaft; install the pin (39) through the

that secure the oil pump to the center

gear and shaft.

bearing cap; remove the oil pump.

(4) Check the clearance of the gears in the

b. Disassembly (fig. 59).

pump body (fig. 66); there should be

(1) Remove the cotter pin (28) that secures

0.001 to 0.003inch clearance in the

-

the float assembly (27) to the oil pump

chamber. The gears should not contact

cover (31); remove the float.

the chamber walls.

(2) Remove the screws (29) and lockwashers

(5) W ith the cover gasket (32, fig. 59) in

(30) that secure the cover (31) to the

place on the body, there should be

body; remove the cover, gasket (32), and

0.0015- to 0.006 inch clearance between

-

idler gear (26).

the gears and the cover (fig. 67). Install

the cover (31, fig. 59).

(3) Remove the pin (39) that secures the

drive gear (40) to the drive shaft (36);

(6) Install the float assembly (27) on the

remove the gear from the shaft. Remove

pump body.

the assembled driver gear (34) and drive

shaft from the pump body.

(4) Remove the retaining ring (33) from the

lower end of the drive shaft; remove the

driver gear and key (35) from the drive

shaft.

c. Cleaning and Inspection (fig. 59).

(1) Thoroughly clean all parts with an

approved cleaning solvent; dry with clean,

dry, compressed air.

(2) Check the fit of the drive shaft (36) in the

bearing (38) in the top of the oil pump

Figure 66. Checking oil pump gear clearance.

body (37) and in the bearing (41) in the

press in new parts if the old ones are

loose or worn.

TAGO 6358-A

77