TM 5-3825-270-23&P

FIELD MAINTENANCE

ROLLER REPAIR

INITIAL SETUP:

Materials/Parts (cont.)

Tools and Special Tools

Cleaning Compound, Solvent (WP 0224, Table 1,

Compressor Unit, Air (WP 0225, Table 1, Item 2)

Item 10, 11, 12, 13, 14, 15)

Gloves, Rubber (WP 0225, Table 1, Item 2)

Pin, Cotter (WP 0226, Table 1, Item 15) Qty: 1

Goggles, Industrial (WP 0225, Table 1, Item 12)

Gun, Air Blow (WP 0225, Table 1, Item 2)

Tool Kit, General Mechanic's: Automotive

References

(WP 0225, Table 1, Item 12)

Parts Manual (WP 0220) Figure 4003

Materials/Parts

Equipment Condition

Cloth, Cleaning, Low-Lint (WP 0224, Table 1, Item

Roller removed. (TM 5-3825-270-10)

16, 17)

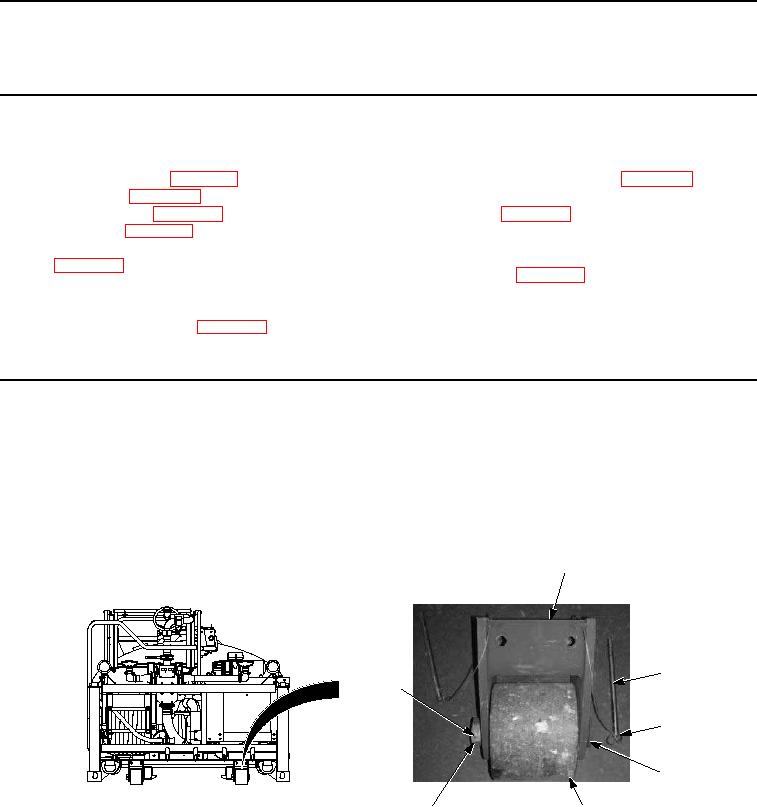

DISASSEMBLY

NOTE

Both left and right rollers are repaired the same way. Right side shown.

Note and tag location of roll pin and collar prior to removal to ensure proper installation.

1.

Remove cotter pin (Figure 1, Item 1) from collar (Figure 1, Item 7). Discard cotter pin.

2

3

1

4

5

7

6

Figure 1. Roller Disassembly.

2.

Remove collar (Figure 1, Item 7), roller shaft (Figure 1, Item 5), and roller (Figure 1, Item 6) from bracket (Figure

1, Item 2).

NOTE

Perform Step (3) if retaining pins are damaged.