TM 10-4320-344-24

3.6.4 Pump Casing Assembly Repair, Model US636HCCD-1.

This task covers:

3 .6.4.1 Disassembly

3.6.4.3 assembly

3 .6.4.2 Repair

INITIAL SETUP

Tools

Equipment Conditions

General Mechanic’s Automotive

Pumping station shut down, TM 10-4320-344-

Tool Kit, Appendix B, Section III,

10.

Item 1

Suction Elbow and Discharge Elbow removed,

Puller Kit, Mechanical, Gear and

paragraph 2.18.2.

Bearing, Appendix B, Section III,

Item 3

Intermediate Bracket Assembly removed,

paragraph 3.6.2.

Tap and Die Set, Appendix B,

Section III, Item 3

General Safety Instructions

Tool Kit, Coil Insert, Appendix B,

Do not work on equipment that is not

Section III, Item 3

securely stabilized to prevent rolling

o r s l i d i n g.

Materials/Parts

Do not work on equipment without follow-

Antisieze Tape, Appendix C, Item 32

ing standard shop safety practices.

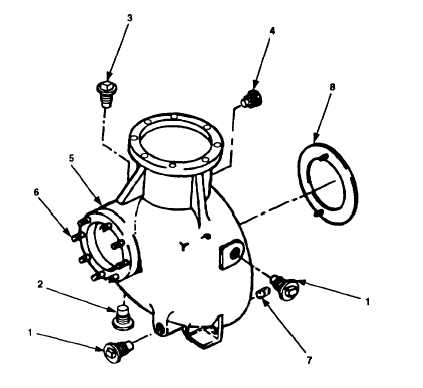

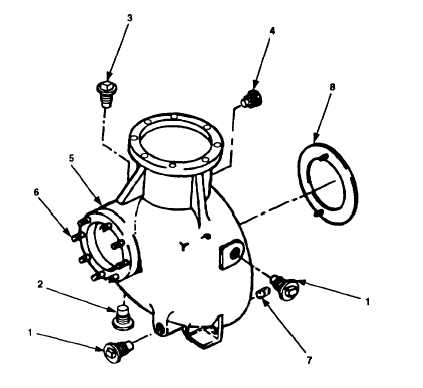

3.6.4.1 Disassembly. Remove two plugs (Figure 3-5, 1) and plugs (2, 3, and 4) from

pump casing assembly (5).

Figure 3-5. Pump Casing Assembly Repair, Model US636HCCD-1.

3-17