TM 5-4320-302-14

Table 4-2. Organizational Maintenance Troubleshooting - Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 5. Make sure that exhaust primer assembly works properly.

Replace defective exhaust valve primer assembly (para 4-18).

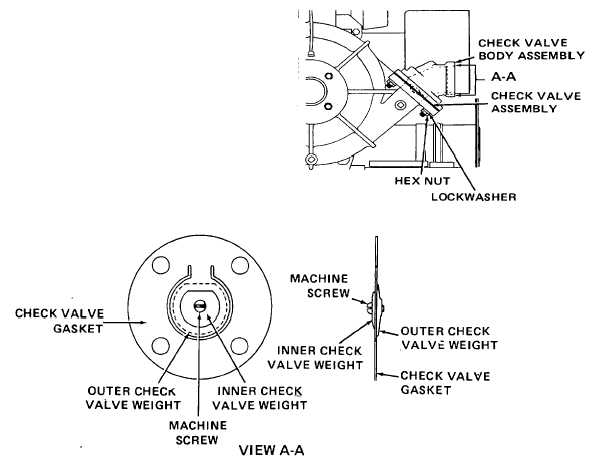

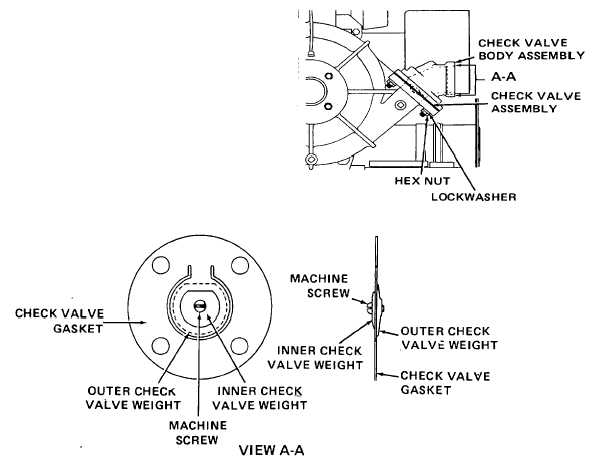

Step 6. Inspect check valve assembly for proper operation. Inspect check valve body

assembly for cracks or damaged threads. Check that attaching hardware is tight

and free of corrosion. Inspect check valve assembly for evidence of leakage,

gasket damage, and presence

of outer check valve weight.

Machine screw shall be

tight. All components must

be free of corrosion. When

in closed position, check

valve gasket flapper must

make an airtight seal on

pump outlet. Be sure valve

gasket flapper is free to

open with pump flow.

Replace check valve

assembly (para

4-19).

9. PUMP OUTPUT LOW

Step 1. Check that engine speed is properly adjusted for desired flow and conditions.

Adjust engine speed (para 2-5).

Step 2. See Malfunction 8, steps 1 thru 6.

Step 3. See Malfunction 8, steps 4 and 5.

Step 4. See Malfunction 8, step 6.

4-45