TM 5-4320-300-14

6-10. PISTONS AND CONNECTING RODS (CONT)

Location/Item

Action

Remarks

35. Piston rings

If gap on new compression ring is insufficient, it

may be increased by filing or stoning the ends

of the ring. File or stone both ends of ring so

cutting action is from outer surface to inner sur-

face. This will prevent any chipping or peeling of

chrome plate on ring. The ends of the ring must

remain square and chamfer on outer edge must

be approximately 0.015 inch (0.381 mm). Re-

place a new oil control ring which fails to meet

ring gap tolerance. If piston ring side clearance

exceeds the limit, replace piston.

REASSEMBLY

36. Piston pin

If bushings were removed during overhaul,

bushings

install new bushings.

(in piston)

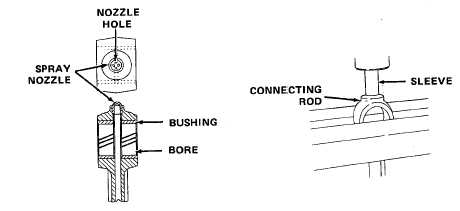

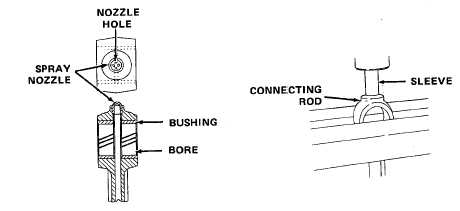

37. Connecting

Start replacement spray nozzle into connecting

rod spray

rod counterbore with the holes in a diamond

nozzle

pattern sideways to the bushing bore. Support

connecting rod in an arbor press. Place a short

3/8 inch (9.53 mm) inner diameter sleeve on

top of nozzle. Press nozzle into counterbore

until it bottoms.

38. Connecting

Clamp upper end of connecting rod assembly.

rod bushings

Start a replacement bushing straight into bore of

connecting rod, with bushing joint at top of rod.

Drive bushing in connecting rod. Turn rod over

and install second bushing in the same way.

NOTE

Bushings must be able to stand an end load of 2000 pounds (907 kg). If

bushing slides in easy, it probable will not stand the required end load.

Replace bushings or connecting rod if necessary.

6-87