TM 5-4320-300-14

6-10. PISTONS AND CONNECTING RODS (CONT)

Location/Item

Action

Remarks

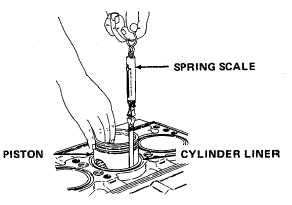

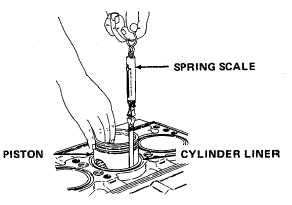

21. Piston-to-

Hold piston upside down in

liner clear-

cylinder liner (liner in block).

ance

When performing piston-to-

liner clearance inspection, use

a feeler gage that is perfectly

flat and free of all nicks and

bends. Use a spring scale to

select a feeler gage with a

thickness which will require

a pull of 6 pounds (2.7 kg)

to remove. The clearance

will be 0.001 inch (0.0254

mm) greater than the thick-

ness of the feeler gage used.

If binding occurs, inspect piston and liner for

burrs. Remove burrs with a fine hone and re-

check clearance. Piston-to-liner clearance (with

new piston and liner) should be 0.0031 to

0.0068 inch (0.0787 to 0.1727 mm). A maxi-

mum clearance of 0.010 inch (0.254 mm) is

allowable with used parts.

NOTE

Each piston is fitted with a fire ring, three compression rings, and two oil

control rings. The top compression (fire) ring can be identified by the

bright chrome on the bottom side and oxide (rust color) on the top. The

second compression ring can be identified by its cast iron construction.

A two-piece oil control ring is used in both oil ring grooves. All new piston

rings must be installed whenever a piston is removed, regardless of whether

a new or used piston or cylinder liner is installed.

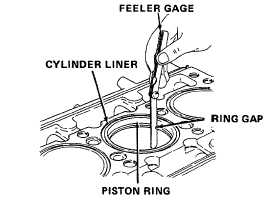

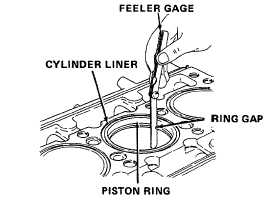

22. Piston ring

Use piston to push new rings, one at a time,

Push ring in far

gap

down into the cylinder liner. With a feeler

enough to be in the

gage, measure ring gap according to the

normal area of ring

following chart.

travel.

6-84