TM 5-4320-300-14

6-10. PISTONS AND CONNECTING RODS (CONT)

Location/Item

Action

Remarks

13. Piston pin

Inspect for excessive wear or scoring.

bushings

(in piston)

14. Pin-to-bushing

Slide piston pin back into bushing and meas-

clearance

ure pin-to-bushing clearance. The maximum

allowable clearance with new parts is 0.0034

inch (0.0864 mm). The maximum allowable

clearance for worn parts is 0.010 inch

(0.254 mm).

15. Piston pin

Inspect bushings for scoring, overheating, or

bushing (in

other damage. Notice whether bushings have

connecting

moved closer (crept) together in connecting

rod)

rod.

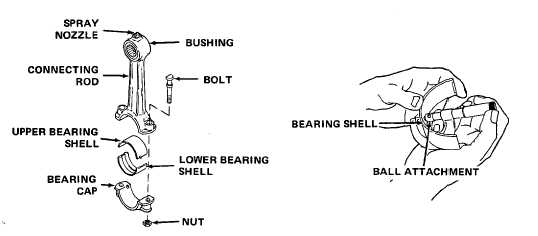

CAUTION

Connecting rod bearing and journal damage may occur if bearing shells and

caps are mixed up. Matchmark shells and caps prior to disassembly.

16. Connecting

Remove bearing cap nuts. Remove bearing cap.

rod bearing

Remove bearing shells. Inspect upper and

shells

lower bearing shells for excessive wear, scoring,

pitting, flaking, etching, and signs of overheat-

ing. Inspect bearing shell backs for bright spots

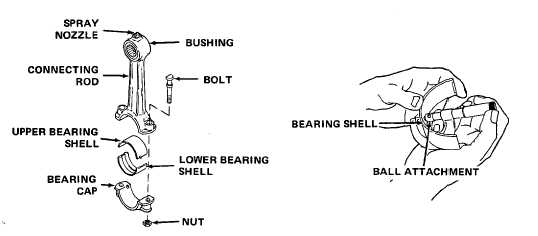

(bearing moving in supports). Measure bearing

shells with a micrometer and ball attachment.

The minimum thickness of a worn standard

connecting rod bearing shell is 0.1230 inch

(3.1242 mm).

6-82