TM 5-4320-300-14

6-10. PISTONS AND CONNECTING RODS (CONT)

Location/Item

Action

Remarks

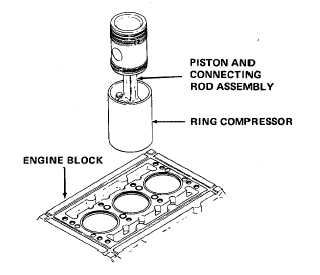

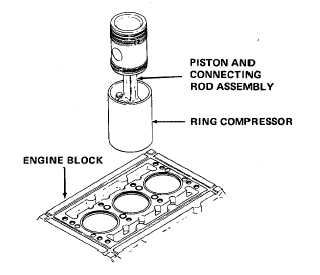

44. Piston and con-

Position piston and connecting rod assembly

necting rod

and ring compressor in line with the block

assemblies

bore so that identification number on rod is

facing engine serial number side. Slide piston

and connecting rod assembly through ring

compressor and push or pull piston and con-

necting rod into liner until upper bearing

shell is firmly seated on the crankshaft

journal.

45. Connecting

Place lower bearing shell in bearing cap, with

rod lower

tang on shell in notch in cap. Lubricate bearing

bearing shells

shell with clean MIL-L-2104 oil.

CAUTION

Equipment damage may occur if connecting rod bolt turns before torque

is applied to nut. Make sure that bolt head is properly seated on con-

necting rod before tightening nut.

46. Connecting

Install bearing cap with bearing shell on con-

rod bearing

necting rod with identification numbers on

caps

cap and rod adjacent to each other. Torque

nuts to 40 to 45 ft lb (54 to 61 N.m).

6-90