TM 5-4320-300-14

6-9. VALVES, CAMSHAFT, AND TIMING GEARS (CONT)

Location/Item

Action

Remarks

CAUTION

Equipment damage may occur if grinding wheels make contact with cyl-

inder head. Grind valve seat inserts as true as possible.

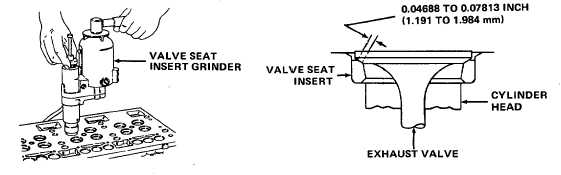

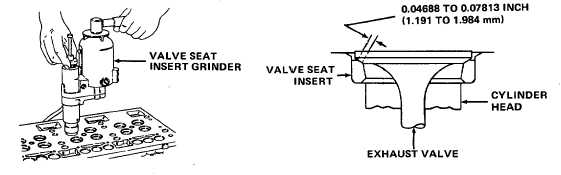

37. Valve seat

Install a 31 degree grinding wheel in valve seat

The 31 degree face

insert

insert grinder and apply the wheel to the insert.

of the insert may be

adjustment

Remove 31 degree grinding wheel from grinder

adjusted relative to

and install a 60 degree grinding wheel. Apply

the center of the

wheel to insert to open throat of insert. Grind top

valve face with the

surface of insert with a 15 degree wheel to narrow

15 degree and 60

the seat width to a range between 0.04688 and

degree grinding

0.07813 inch (1.1908 and 1.9845 mm).

wheels.

WARNING

Severe burns, illness, or death may result if personnel fail to handle diesel

fuel properly. Observe the following precautions:

Do not inhale vapor.

Do not refuel near open flame, sparks, or excessive heat.

Be certain fuel lines and connections are secure.

Work in a well-ventilated area.

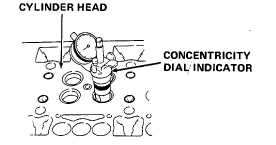

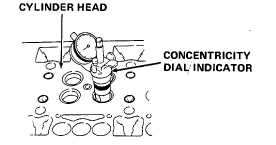

38. Concentricity

Clean the valve seat insert

check

thoroughly with VV-F-800

diesel fuel and dry it with

compressed air. Set con-

centricity dial indicator in

position and rotate it to

determine the concentricity

of each valve seat insert

relative to the valve guide.

If runout exceeds 0.002

inch (0.0508 mm), inspect valve guide for bend.

If valve guide is not bent, regrind insert.

6-69