TM 5-4320-300-14

5-18. CYLINDER HEAD AND BLOCK (CONT)

Location/Item

Action

Remarks

WARNING

Make sure that hoists and other lifting equipment are in good repair and of

sufficient capacity to safely handle loads without injury to personnel or

damage to equipment. Securely attach lifting equipment to cylinder head.

Before lifting, be sure load is balanced.

13. Cylinder

Ensure that all seals are in place and wipe mating

head

surface of cylinder head clean. Attach lifting de-

vice to cylinder head and lower head to approxi-

mately 1/2 inch (12.7 mm) above cylinder block.

CAUTION

Engine damage may result if ordinary bolts are used to secure cylinder

head. Cylinder head bolts are specially designed for this purpose.

Compression leaks may result if bolts are torqued beyond recommended

limits, or if they are tightened in one step.

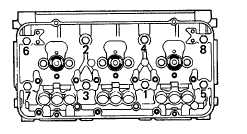

14. Cylinder

Apply a small quantity of

head bolts

MIL-T-22361 thread com-

pound to threads and

underside head of each

bolt. Install bolts hand

tight as head is lowered

onto the block. Torque

all bolts to 15 to 20 ft

lb (20 to 27 N.m). Then

torque bolts to 170 to

180 ft lb (231 to 244 N.m) in 50 ft lb (68 N.m)

increments in the order shown.

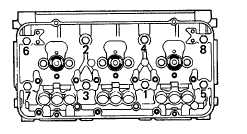

NOTE

Repeat tightening sequence at least once, because first bolts tightened in

sequence tend to lose significant clamp load during tightening of

remaining bolts. Apply a steady pressure of 2 or 3 seconds at the

prescribed torque to allow bolts to turn while gaskets yield to their final

designed thickness. Begin on cam follower side of head to take up

tension in push rod springs. Torque bolts to the high side of the torque

specification.

5-75