TM 5-4320-300-14

Table 5-1. Direct Support Troubleshooting-Continued

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

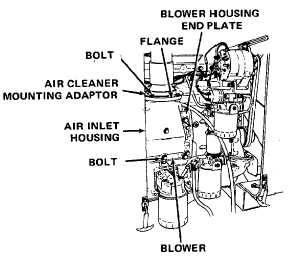

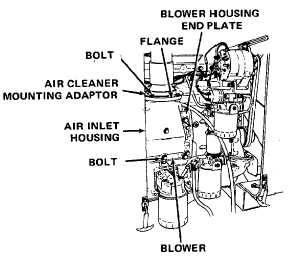

Step 2. Check for damaged blower oil seals. Remove air cleaner mounting adaptor bolts. Remove air inlet

housing bolts and carefully slide housing from beneath adaptor.

NOTE

The gasket between air cleaner mounting adaptor and air inlet housing flange may stick when air

inlet housing is removed.

Start engine and inspect blower front and rear plates while the engine is operating. If oil is seen on

the plates radiating away from the oil seals, replace blower assembly (para 5-9).

Step 3. Check for oil cooler core leaks.

WARNING

Hot coolant may be released when radiator cap is removed. Allow engine to cool before removing

cap. Open cap part way to ensure that pressure in cooling system is released, then remove cap.

Inspect engine coolant at radiator cap. If coolant contains oil, notify general support maintenance.

6. PUMP DOES NOT DISCHARGE OR HAS LOW DISCHARGE PRESSURE

Step 1. Check for broken impeller. Disassemble pump (para 5-21). Inspect impeller.

Replace impeller if necessary.

7. PUMP MAKES EXCESSIVE NOISE

Step 1. Check for foreign matter in pump. Disassemble pump (para 5-21). Inspect for foreign matter.

Remove foreign matter.

5-5