TM 5-4320-300-14

5-2. SYMPTOM INDEX

Refer to the Symptom Index below. Locate the malfunction which is the same, or most nearly the same, as the trouble

you are having with the pump assembly. The Symptom Index lists the first page of troubleshooting information for that

malfunction. Follow the steps one by one, and perform the corrective actions listed.

Malfunction

Number

Description

Page

1

Engine fails to crank or cranks at low speed

5-2

2

Engine cranks but fails to start

5-2

3

Engine starts but runs unevenly, stalls, or surges

5-3

4

Engine stops running or produces black, white, or grey smoke

5-3

5

Engine consumes excessive lube oil

5-4

6

Pump does not discharge or has low discharge pressure

5-5

7

Pump makes excessive noise

5-5

Table 5-1. Direct Support Troubleshooting

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.ENGINE FAILS TO CRANK OR CRANKS AT LOW SPEED

Step 1. Check for faulty starter motor. Remove and test (para 5-6).

Repair faulty starter motor (para 5-6).

2. ENGINE CRANKS BUT FAILS TO START

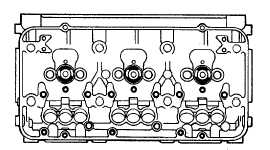

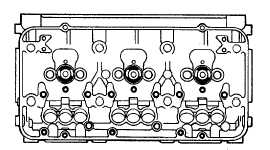

Step 1. Check for loose cylinder head bolts.

If loose, tighten in the sequence shown to 170 to 180 ft lb (231 to 244 Nm).

Step 2. Check for compression gasket leakage. Remove radiator cap and crank the engine. A steady flow

of gases bubbling to the surface of the coolant indicates either a damaged compression gasket or

cracked cylinder head.

Remove cylinder head and replace compression gaskets (para 5-18). If replacing compression

gaskets does not eliminate gas bubbles at coolant surface, replace the cylinder head (para 5-18).

5-2