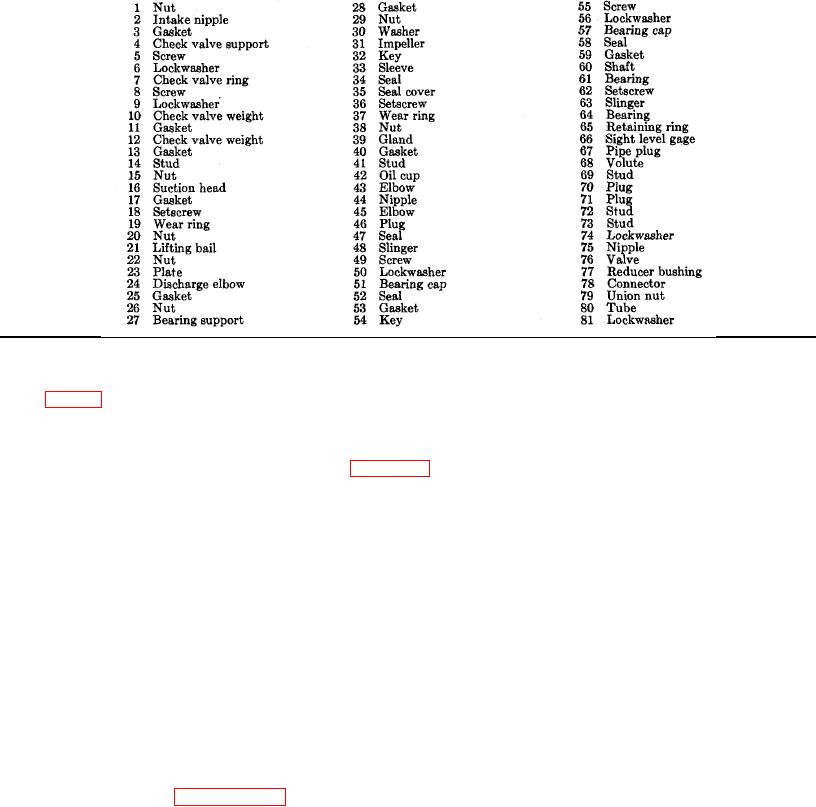

INDEX TO FIGURE 74

(6) Inspect all gaskets for damage; replace if

127. Impeller, Shaft, Seal and Bearings

damaged.

(7) Inspect seal (58) for wear or damage:

replace if worn or damaged.

a. Removal and Disassembly

.

Remove and

(8) Inspect all other parts for cracks, bre s,

ak

disassemble the impeller, shaft, seal, and bearings in order

stripped threads, wear, or other damage;

of index numbers 26 through 67 assigned to figure 74.

replace if damaged.

Observe the following special instructions:

c. Assembly and Installation Assemble and

.

(1) Press the assembled shaft (60) and bearing

(61) out of the coupling end of the bearing install impeller, shaft, seal, and bearings making. sure

support (27). Loosen the setscrew (62) and the shielded portion of the bearings are facing the

remove the slinger (63) from the shaft. Press bearing caps.

Observe the following special

instructions:

the bearing (61) from the shaft.

(1) Press the bearing (64) onto the shaft.

(2) Press the bearing (64) from the bearing

Position the slinger (63) on the shaft;

frame. Remove the retaining ring (65) from

secure with the setscrews (62).

the bearing frame.

(2) Install the retaining ring (65) in the

b. Cleaning and Inspection.

bearing frame.

Press the assembled

(1) Clean all metal parts except bearings and

shaft, slinger, and bearing into the bearing

seals with an approved cleaning solvent; dry

frame until the bearing bottoms on the

with clean, dry, compressed air.

retaining ring.

(2) W ipe gaskets with a damp cloth.

(3) Install the bearing (61) into the bearing

(3) Clean seals with a cloth dampened with

frame and onto the shaft. Tighten the

cleaning solvent. Do not allow solvent to

screws (49 and 55) that secure the

contact rubber or synthetic materials.

bearing caps (51 and 57) evenly and

(4) Clean, lubricate, and inspect bearings as

alternately to make sure the bearings seat

directed in paragraph 106c.

squarely without binding.

(5) Inspect seal (34) for spring distortion, wear, or

(4) Rotate the shaft after assembly to make

defects; replace if defective.

sure the parts ride freely.

TAGO S358A

87