TM 10-4320-344-24

4.4.15 Piston and Connecting Rod Assembly Maintenance, Models 609-C and US636HCCD-1. (Continued)

4.4.15.2 Repair.

If piston does not meet inspection requirements, is defective or damaged, and

needs to be replaced, the piston pin, piston rings, and cylinder must also be

replaced.

a .

Inspect piston (1) and piston rings (9) for cracks, chips, and burrs. Ensure

piston (10) ring grooves are free of foreign matter.

b.

Using piston ring, insert pin on gauge into first ring groove of piston (1).

If gauge body touches piston (1), piston (1) is defective.

c .

Using micrometer, inspect piston (1) to the dimensions listed in Table 4-9.

The values in { } are for Model US636HCCD-1 when different from Model 609-C.

Table 4-9. Piston Dimensions, Models 609-C and US636HCCD-1.

Dimension

Minimum

Maximum

Diameter

3.9331 inches (99.901 mm)

3.9338 inches (99.919 mm)

{4.0107 inches (101.872 mm)}

(4.0121 inches (101.907 mm)}

Number of oversizes

2 {1}

Distance between

0.0394 inches (1.000 mm)

0.0472 inches (1.200 mm)

piston and cylinder

head

Bore for piston pin

1.3780 inches (35.000 mm)

1.3782 inches (35.006 mm)

{1.5748 inches (40.000 mm)}

{1.5750 inches (40.006 mm)}

2nd and 3rd ring

0.0988 inches (2.509 mm)

0.1028 inches (2.610 nun)

groove height

{0.1016 inches (2.580 mm)}

{0.1024 inches (2.600 mm)}

4th ring groove

0.1980 inches (5.030 mm)

0.1988 inches (5.050 mm)

height

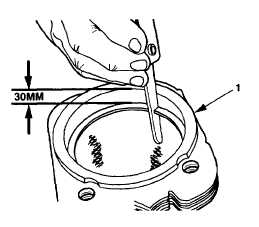

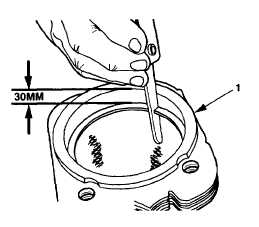

Figure 4-26. Piston Ring Gap Measurement, Models 609-C and US636HCCD-1.

d.

Insert ring into cylinder (Figure 4-26, 1). Use piston to push ring down to a

point 1.18 inches (30 mm) from top of cylinder (1). Measure and record ring

end gap. Remove ring.

4-52

NOTE

NOTE