TM 10-4320-344-24

4.4.10 Flywheel Maintenance, Models 609-C and US636HCCD-1.

This task covers:

4.4 .10.1 Removal

4 .

4 .

1

0 .3

I n s t a l l a t i o n

4 .

4 .1 0 . 2 R e p a i r

INITIAL SETUP

Tools

Equipment Conditions

General Mechanic’s Automotive

Pumping Assembly removed, paragraph

Tool Kit, Appendix B, Section

3 .

6 .

1.

III, Item 1

General Safety Instructions

Acetylene Welding Equipment, Appendix B,

Section III, Item 2

DO not work on equipment that is not

securely stabilized to prevent rolling

Torque Wrench, Appendix B, Section III,

o r s l i d i n g.

Item 2

Do not work on equipment without follow-

Angle-of-Turn Indicator, Appendix B,

ing standard shop safety practices.

Section III, Item 3

4.4.10.1 Removal.

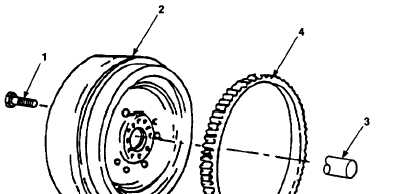

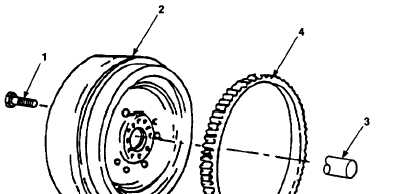

Remove ten flywheel mounting screws (Figure 4-14, 1) and flywheel

(2) from crankshaft (3).

Figure 4-15.

Flywheel Maintenance, Models 609-c and US636HCCD-1.

4.4.10.2 Repair.

a .

Inspect flywheel (2) for cracks, distortions, discoloration, wear, or other

damage.

b .

Inspect ring gear (4) for broken or cracked teeth, chips, or other damage. If

ring gear (4) is damaged, replace as follows:

(1) Remove ring gear (4) from flywheel (3) and discard.

4-33