TM 10-4320-344-24

4.4.9 Flywheel Maintenance, Model 609-A.

This task covers:

4.4.9.1

Removal

4 .4 . 9 . 3 I n s t a l l a t i o n

4 .4 . 9 . 2 R e p a i r

INITIAL SETUP

Tools

General Mechanic’s Automotive Tool Kit,

Appendix B, Section III, Item 1

Acetylene Welding Equipment, Appendix B,

Section III, Item 2

Goggles, Appendix B, Section 111,

Item 2

Torque Wrench, Appendix B, Section III,

Item 2

Material/Parts

Gloves, Appendix C, Item 11

Rags, Appendix C, Item 20

Solvent,

Dry Cleaning, Appendix C,

Item 26

Locker Washer (TM 10-4320-344-24P)

Equipment Conditions

Pumping Assembly removed, paragraph

3 .

6 .

1 .

Starter Assembly removed, paragraph

2.21.18.

General Safety Instructions

Do not work on equipment that is not

securely stabilized to prevent rolling

o r s l i d i n g.

Do not work on equipment without follow-

ing standard shop safety practices.

4.4.9.1 Removal.

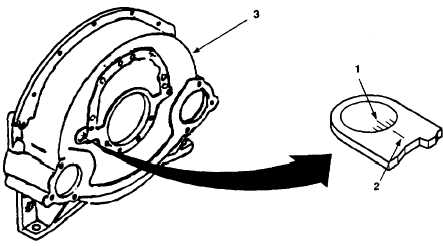

Figure 4-13.

Positioning of Flywheel, Model 609-A.

a.

Turn crankshaft until “DC” mark (Figure 4-13, 1) on flywheel aligns with

timing mark (2) on bellhousing (3).

b.

Secure crankshaft to eliminate crankshaft rotation.

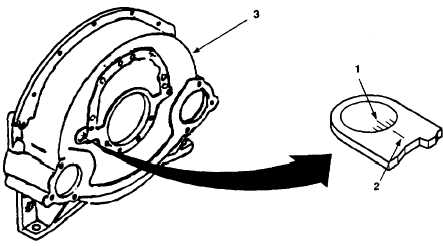

d.

Remove six bolts (Figure 4-14, 1) that secure flywheel (2) to crankshaft (3).

4-30