TM 10-4320-344-24

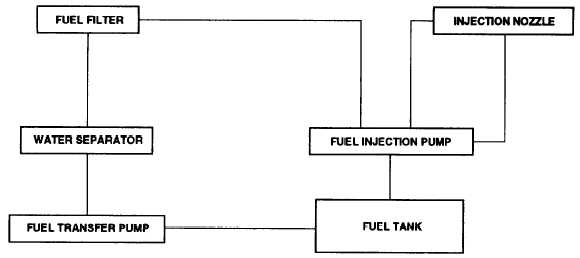

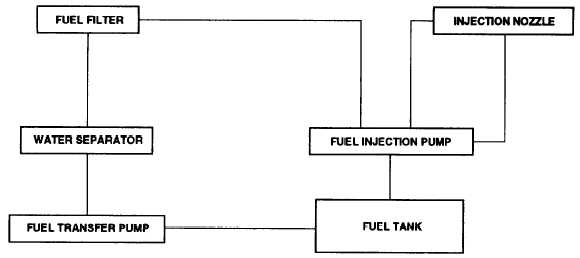

Figure 1-5. Fuel System Functional Block Diagram.

1.15.3 Control Panel.

Controls pump and engine operations. For an illustration and

description of the controls and indicators, refer to TM 10-4320-344-10, Chapter 2,

Section I. When the pumping assemblies are run in the electric automatic mode the

engine speed is controlled by the pressure regulator for the model 609-A and process

controllers and process devices for Models 609-C and US636HCCD-1. The pressure

regulator, process controller, and controlling devices monitor the suction pressure

of the water pump and control engine speed through the engine governor. When the

pump suction pressure drops below 10 pounds per square inch (psi) (69 kilopascal

(kPa)) the engine is reduced to idle speed to prevent damage to the equipment.

Engine speed is also reduced to idle when the suction pressure rises above 120 psi

(827 kPa) to prevent damage to the equipment.

1.15.4 Centrifugal Pump.

The pumping assemblies have the capability of pumping up to

600 GPM at up to 350 feet total discharge head (TDH). The pump is driven by a

direct coupling between the flywheel of the diesel engine and the intermediate

bracket assembly.

1.15.4.1 Pump Casing.

The pump casing is a solid cast metal housing to which the

intermediate bracket assembly and suction and discharge elbows are mounted. The

impeller from the intermediate bracket assembly is fitted in the rear of the pump

casing. As the impeller rotates, a vacuum is created which draws water in through

the suction elbow,

The water is then slung through the impeller and out through the

discharge elbow.

1.15.4.2 Intermediate Bracket Assembly Housing.

The intermediate bracket assembly is the

interface between the diesel engine and pump casing. The intermediate bracket

assembly consists of an impeller, impeller shaft, sealed self-lubricating ball

bearings, cast metal housing, and flexible coupler. The flexible coupler, mounted

on the end of the impeller shaft, is fitted in or over mounting devices attached to

the fly wheel of the diesel engine. As the engine operates the flywheel rotates in

a clockwise direction. The flexible coupler and thus the impeller shaft also

rotates in the clockwise direction. The sealed self-lubricating ball bearings

provide support and spinning capability to the impeller shaft. The impeller is

mounted on the end of the impeller shaft, opposite of the flexible coupler, and is

located inside the pump casing when installed in the pumping assembly. The cast

metal housing is bolted to both the pump casing and the diesel engine for support.

1.15.5 Two-Wheeled Trailer Assembly.

Transports pump and engine unit. All models have

rear lights, an inertia-actuated hydraulic braking system, manually operated park

brakes and leveling jacks, and safety chains.

1-10