TM 10-4320-310-14

Table 2-2. Operator's Preventive Maintenance Checks and Services (Continued)

B -Before Operation

A -After Operation

M - Monthly

D - During Operation

W -Weekly

B

D

A

W

M

10

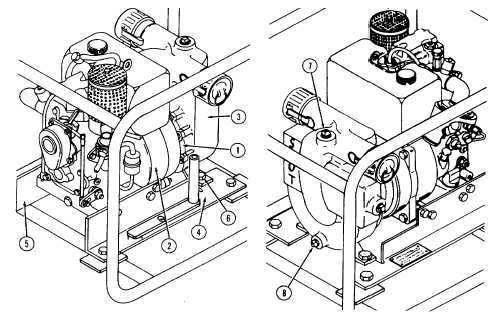

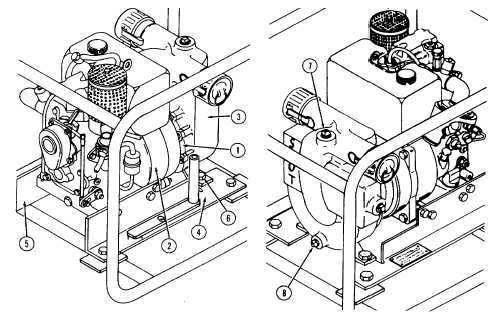

Pump Housing and Backhead

•

•

Check that backhead (1) is securely attached to

Pump housing or

engine (2) and housing (3) is securely attached to

backhead screws

•

•

mounting brackets (4 and 5) with screws (6).

loose or broken.

Check that fill pipe plug (7) and drain pipe plug

(8) is securely installed in housing (3).

•

Listen for unusual noise during pump operation.

Unusual noise

coming from pump

housing and/or

backhead.

•

Check housing (3) and backhead(1) for cracks

Pump housing or

and corrosion.

backhead is cracked

or damaged.

•

Check condition of paint.

Paint shall be in good

condition with no bare metal or corrosion.

INTERVAL

ITEM

NO.

ITEM TO BE INSPECTED

PROCEDURE

Equipment is

Not Ready/

Available If

2-22