TM 10-4320-307-24

4-18

CYLINDER BLOCK INSPECT/REPAIR/REPLACE (CONT).

CLEANING:

Live steam used for cleaning shall not exceed 100 psi (690 kPa). During

steam cleaning operations, adequate ventilation, natural or forced, should be

provided.

Do not direct live steam against skin.

Dry cleaning solvent is potentially dangerous. Avoid repeated and prolonged

breathing of vapors and skin contact with the liquid. Do not use near open

flame, arcing equipment, or other ignition source. Always wear eye protection

and protective clothing.

Death or serious Injury could occur If compressed air is directed against the

skin.

Do not use compressed air for cleaning or drying unless the pressure is/has

been reduced to 30 psi (2.11 kgcm2) or less. When working with compressed

air always use chip guards, eye protection, and other personal protective

equipment.

1.

Clean cylinder block thoroughly with live steam. Clean all exterior and interior openings and surfaces. Be especially

careful to dean all oil passages to make sure they are open. Use a wire bristle brush where necessary to remove

carbon or other deposits from openings and surfaces. Use dry cleaning solvent as necessary to soften and remove

carbon or hardened oil deposits. Dry with compressed air.

2.

Chase threads in engine block with appropriate tap.

3.

Clean cylinder liners with warm water and soap. Using a bristle brush, clean soap from cylinder liners with live steam

and dry with compressed air. Apply a light coat of lubricating oil to the liners.

INSPECTION:

1.

Thoroughly inspect cylinder block for any cracks, discoloration, distortion, rust, corrosion, or other damage. Use MIL-

1-6868 magnetic particle inspection to detect cracks. If cylinder block is cracked, distorted, overheated, seriously

rusted or corroded on machined surfaces, or exhibits other serious damage, replace engine block.

2.

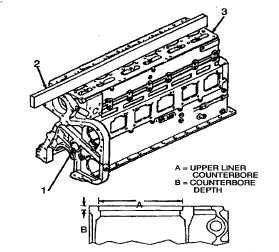

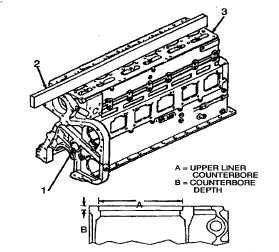

Inspect camshaft bushing bore (1) in cylinder block; camshaft

bushing bore shall not exceed 2.6255 inches (66.688 mm).

3.

Inspect top of cylinder block for flatness or distortion. Place a

straight edge (2) along top of deck (3). Insure a 0.002 inch (0.05

mm) feeler gauge will not fit between block deck and straight

edge.

4.

Inspect upper counterbore for cylinder liner. Measure diameter of

counterbore (A), or if depth of counterbore (B) is more than 0.412

inches (10.466 mm), counterbore must be repaired by installing a

sleeve.

5.

Measure depth of counterbore at four equally spaced points at

edge of bore. There must not be more than a total of 0.001 inch

(0.03 mm) difference in measurements around circumference of

counterbore.

6.

The ledge must be flat with top of block within 0.0014

inch

(0.036 mm) overall.

4-138