TM 10-4320-307-24

4-17

CRANKSHAFT ASSEMBLY REPLACE,REPAIR (CONT)

5.

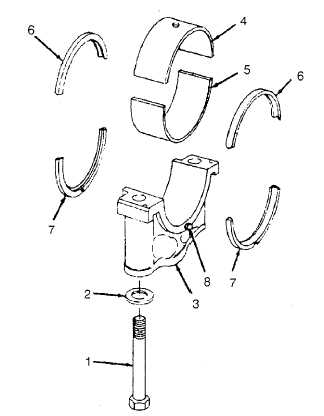

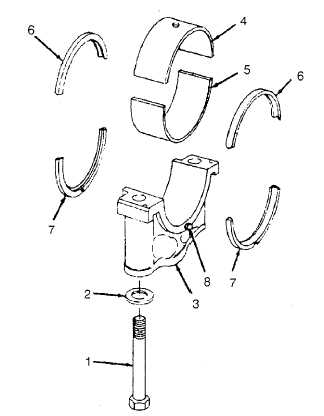

Install hexagon screws (1) and washers (2) in

each bearing cap (3).

6.

Coat upper and lower main bearing shells (4

and 5) with lubricating oil.

NOTE

The upper main bearing shells have a

groove and an oil hole to provide

crankshaft lubrication. The lower main

bearing shells do not. The groove for the

No. 7 shell is not in the center of the shell.

The wider part of the No. 7 shell must be

installed toward the flywheel end of the

cylinder block.

7.

Install upper main bearing shells (4) into bearing

brackets

of

crankcase,

In

accordance

with

markings made during removal. If new shells are

used, be sure that correct part number shells are

used at each location.

8.

Install lower main bearing shells (5) into bearing

caps (3), in accordance with markings made dur-

ing removal.

CAUTION

Grooves in thrust rings must be toward the crankshaft.

9.

Coat thrust rings (6 and 7) with clean lubriplate 105, or equivalent, and install upper thrust rings (6) in No. 7 main

bearing saddle in crankcase. Refer to location markings on rings made during disassembly.

10. Install lower thrust rings (7) in No. 7 main bearing cap as shown, in accordance with markings made on rings during

removal. Be sure that locating dowels (8) in bearing cap fit into dowel holes in rings.

11. Lubricate threads of hexagon screws (1) and washers (2) with lubricating oil and drain excess oil before installing.

4-133