TM 10-4320-307-24

4-18

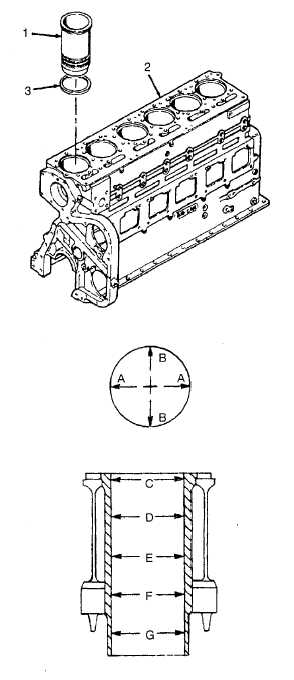

CYLINDER BLOCK INSPECT /REPAIR/REPLACE(CONT).

7.

Inspect cylinder liner protrusion by installing cylin-

der lines (1) in cylinder block (2). Do not put O-

rings on cylinder liners. Use cylinder liner hold

down clamps to hold liner in cylinder block. Make

sure clamps are installed so that there is equal

pressure on liner. Tighten clamps to 50 ft-lbs (68

Nm).

NOTE

Do not use shims for the cylinder

liner unless the counterbore has

been re-

paired.

8.

Use gauge block to measure liner protrusion.

Shims (3) can be placed under flange of cylinder

liner to make liner protrusion the required 0.003 to

0.006 inch (0.08 to 0.15 mm).

9.

Inspect clearance between liner and lower bore. The

clearance must not be more than 0.006 inch (0.15

mm). The cylinder liner can touch lower bore if

touching lower bore does not cause liner bore to be

out of round.

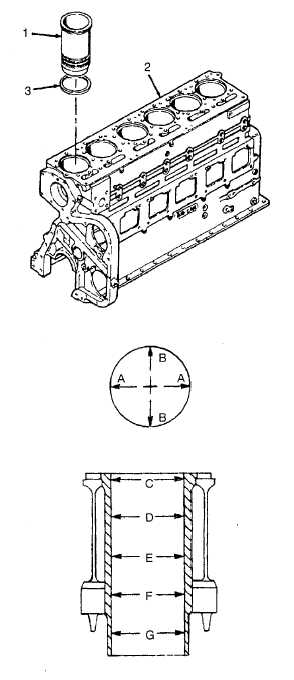

10. Inspect cylinder liner bore for out of round as follows:

a.

Measure bore at points C, D, E, F, and G.

Measure each point in directions AA and BB.

b.

At point C, which is approximately 1 inch (25.4

mm) below top of liner, liner bore can not be more

than 0.003 inch (0.08 mm) out of round.

11. Inspect piston cooling nozzle for blockage and

cracks.

4-139