TM 10-4320-307-24

4-6

SPEED INCREASER REPAIR (CONT).

NOTE

Do not heat the gear nor cool the shaft.

(4) If advance is in acceptable range, press gear onto shaft so that it is flush with shoulder on shaft at small end

of taper. The gear must be advanced to within +0.000/-0.002 inch (+0.000/-0.05 mm) of the shaft shoulder.

NOTE

Inner races of tapered roller bearings may be

pressed on cold, or heated in a 275°F (134.7 C)

oven for not more than 30 minutes. If the bearings

are heated, they must be seated with a press after

cooling.

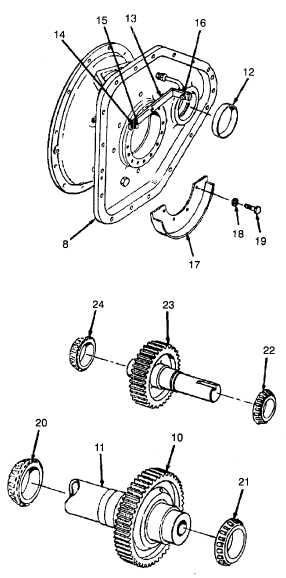

g.

Install tapered roller bearing outer race (12) into

gear front housing (8).

h.

Install tube support bracket (13) with two

lockwashers (14) and two screws (15) onto front

housing (9).

i.

Connect nut (16) and torque screws to 27 2 ft-

lbs (36.60 2.71 Nom).

j.

Install front baffle (17) and secure with four

lockwashers (18) and four screws (19).Torque

screws to 27 2 ft-lbs (36.60 2.71 N.m).

CAUTION

Special tools for seating tapered roller bearings

must have inside diameters slightly larger than

the shaft, and outside diameters small enough

not to touch the cages and rollers.

NOTE

Inner races of tapered roller bearings may be

pressed on cold, or heated in a 275°F (134.70C)

oven for not more than 30 minutes. If the bearings

are heated, they must be seated with a press after

cooling.

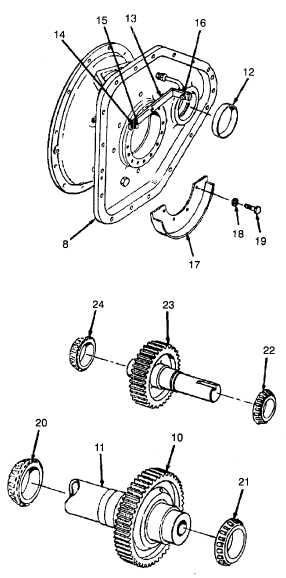

k.

Install inner race of bearing (20) over front of

input shaft (11) and seat. Install inner race of

bearing (21) over rear of input shaft (11) and

seat.

I.

Install inner race of bearing (22) onto rear of

output shaft (23) and seat.

m. Install inner race of bearing (24) onto front of

output shaft (23) and seat.

4-28