TM 10-4320-307-24

4-6

SPEED INCREASER REPAIR (CONT).

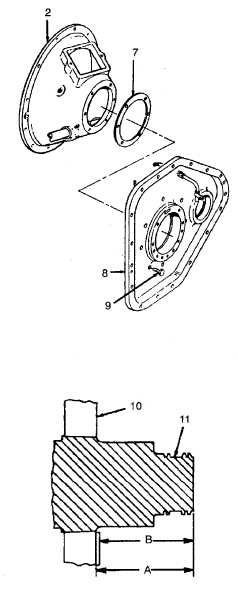

e.

Position gasket (7) in place in speed increas-

er housing (2). Secure front gear housing (8)

to speed increaser housing (2). Apply adhe-

sive sealant to screw threads (9) and torque

screws (9) to 65 +5 ft-lbs (88.12 6.78 N.m).

f.

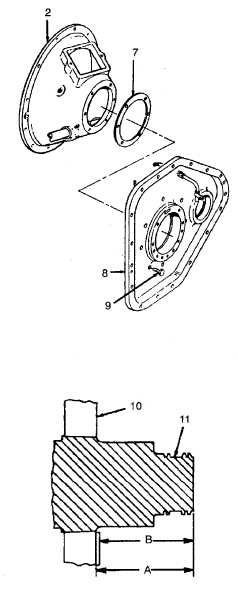

Install input gear as follows:

(1) Clean mating surfaces of input

gear (10) and shaft (11) with dry clean-

ing solvent.

CAUTION

Be careful not to touch these sur-

faces. Do not allow any oil or dirt to

get on them.

(2)

Install input gear (10) onto input

shaft (11) and apply 200 lbs (889.64 N)

force to seat it into its initial position.

(3)

Measure and record dimensions A and B. Advance is A minus B. The advance must be between 0.083 inch

(2.10 mm) and 0.125 inch (3.17 mm). If advance is not within this range, either a different shaft or different gear must be

selected. Should removal of gear be necessary at this time, a sharp rap on front of gear with a rubber hammer should

separate shaft and gear.

4-27