INTERVAL

ITEM

NO.

ITEM TO BE INSPECTED

PROCEDURE

Equipment is

Not Ready/

Available

TM 5-4320-306-10

Table 2-2. Preventive Maintenance Checks and Services Continued

B - Before Operation

A - After Operation

D - During Operation

W - Weekly

B

D

A

W

12

Pump Assembly.

Equipment damage is

indicated by

While unit is operating, listen to the pump assembly

continuous,

components.

excessive noise.

There is evidence

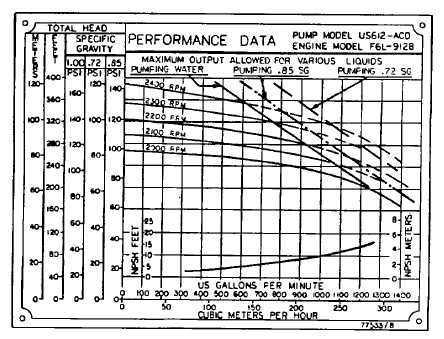

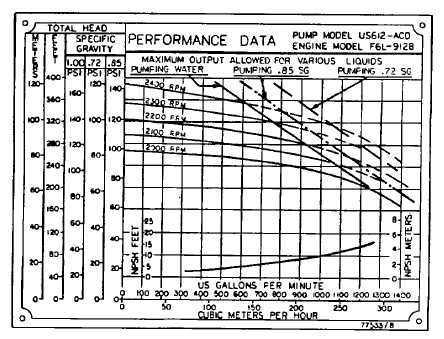

Excessive noise in the pump body may indicate

of Class III leaks.

impeller binding or misalinement. A banging

noise in the pump body may be impeller

cavitation. This is corrected by reducing engine

speed, opening the suction gate valve, or a

combination of both. If cavitation occurs, consult

the performance data plate for proper engine

speed for the specific gravity liquid being pumped.

Noise behind the flywheel guard indicates a

loose or faulty coupling.

TM 5-4320-306-10

2-24