INTERVAL

ITEM

NO.

ITEM TO BE INSPECTED

PROCEDURE

Equipment is

Not Ready/

Available

TM 5-4320-306-10

Table 2-2. Preventive Maintenance Checks and Services Continued

B - Before Operation

A - After Operation

D - During Operation

W - Weekly

B

D

A

W

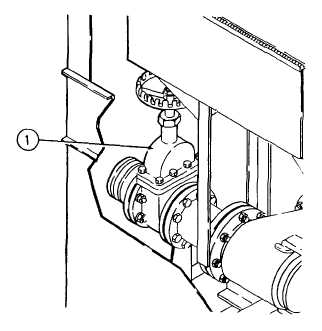

7

Gate Valve (Suction).

Gate valve cannot

open or close.

Check that gate valve (1) operates freely from full

open to full close and back.

8

Discharge Manifold Assembly.

Components and

support brackets

Check bolts (1), nuts and lockwashers (2), and support

are not securely

brackets (3) that secure discharge manifold assembly

mounted. Check to

(4) to pump body (5), and to skid (6). Check that

valve spring is

support brackets are in place and securely mounted.

missing or does

The support brackets, bolts, nuts, and lockwashers

not allow pump

must be free of damage and corrosion.

to build prime.

Hoselines cannot

Visually inspect flanges (7), gaskets (8), or flange

be attached to

nuts and lockwashers (9) for misalinement or damage

victaulic coupling.

that would cause leaks.

There is evidence

of Class I II leaks.

2-19