TM 5-4320-300-14

6-11. CRANKSHAFT AND FLYWHEEL (CONT))

Location/Item

Action

Remarks

INSPECTION OF

CRANKSHAFT

15. Keyway

Inspect for cracks or wear. Replace crankshaft,

if necessary.

16. Crankshaft

Inspect for signs of overheating. Replace crank-

shaft, if necessary.

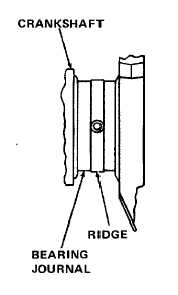

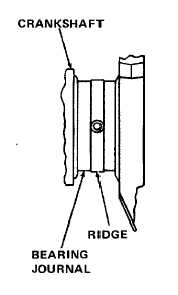

17. Bearing

Inspect for ridges. Ridges exceeding 0.0002 inch

journals

(0.00508 mm) must be removed by working

P-C-458 crocus cloth, wet with VV-F-800 diesel

fuel, around circumference of crankshaft journal.

If ridges are greater than 0.0005 inch (0.0127 mm).

use P-C-1673 emery cloth, 120 grit for removing

ridge and 240 grit for finishing. Polish with wet

crocus cloth. If ridges are greater than 0.001 inch

(0.0254 mm) regrind crankshaft. Use of a piece

of rawhide or other suitable rope wrapped around

the emery cloth or crocus cloth and drawn back

and forth will minimize the possibility of an out-

of-round condition developing (keep the strands

of rawhide apart to avoid bind). If rawhide or

rope is not used, the crankshaft should be

rotated at intervals.

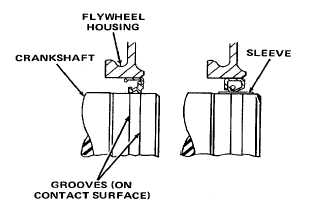

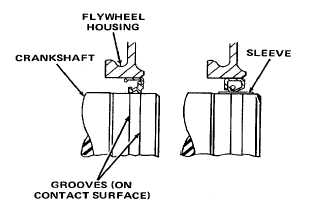

18. Oil seal

Inspect front and rear oil seal contact surfaces for

contact area

grooves or ridges. Remove slight ridges as explained

in step 17 above. If oil seal area cannot be cleaned

satisfactorily, press the oil seals into flywheel hous-

ing or front cover 1/8 inch (3.18 mm) from their

original positions, or install oil seal sleeves to give

the crankshaft replaceable contact surfaces.

19. Oil seal

Install oil seal sleeve on

sleeve on

rear (flywheel housing)

flywheel

contact surface as follows:

housing

surface

a. Stone high spots from

oil seal contact sur-

face of crankshaft.

b. Coat contact surface

with MI L-T-22361

thread compound.

c. Drive sleeve squarely

on the shaft.

d. Wipe off any excess

sealant.

e. Coat outside diameter of sleeve with MI L-L-2104 oil.

TM 5-4320-300-14

6-97