TM 5-4320-300-14

6-11. CRANKSHAFT AND FLYWHEEL (CONT))

Location/Item

Action

Remarks

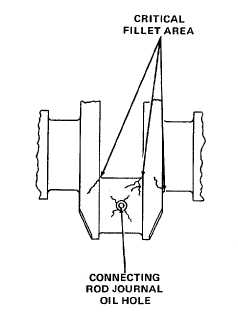

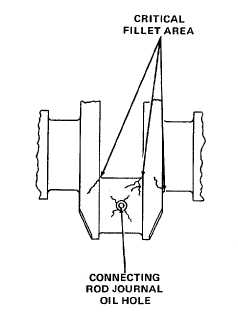

23. Bearing journal

Visually inspect for cracks which start at an

critical areas

oil hole and follow the journal surface at an

angle of 45 degrees to the axis. Inspect for

cracks in critical fillet areas as shown. Re-

place crankshaft if cracks are visible. Inspect

for minute cracks using MIL-1-6868 Magnetic

Particle Inspection.

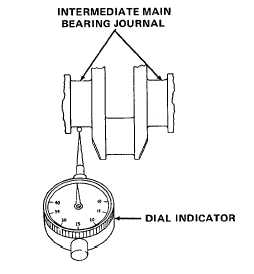

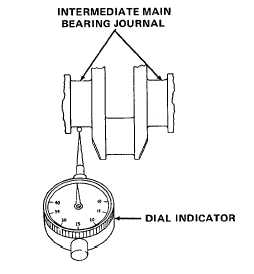

24. Intermediate

Check alignment at adjacent intermediate main

main bearing

journals with a dial indicator. Maximum allowable

journals

runout is 0.002 inch (0.0508 mm). Replace crank-

shaft, if necessary.

6-99