TM 5-4320-300-14

6-8. CYLINDER LINER (CONT)

Location/Item

Action

Remarks

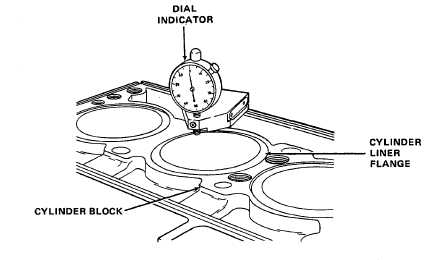

9.

Flange depth

Wipe off block bore, counterbore, and inside and

outside of cylinder liner. Slide liner into block un-

til flange rests on bottom of counterbore. Tap

liner flange lightly all around with a soft hammer

to seat liner flange on bottom of counterbore. Use

dial indicator to measure depth of flange below

block. Flange depth should be 0.0465 to 0.0500

inch (1.181 to 1.27 mm).

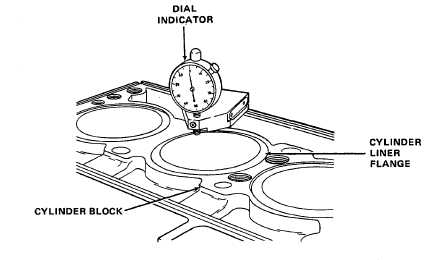

10. Flange depth

Measure variation in flange depth between adjacent

variation

liners. The maximum tolerable variation is 0.002

inch (0.0508 mm). Remove dial indicator.

REPAIR

11. Cylinder

Replace a cylinder liner if:

liner

It is cracked, severely scored, or has a high ridge

replacement

at the top of its inner surface.

Out-of-round or inside taper exceeds the tolerable

limit.

Inside diameter exceeds the tolerable limit.

Outside diameter of seal ring area exceeds the

tolerable limit.

6-51