TM 5-4320-300-14

6-7. CYLINDER HEAD AND BLOCK (CONT)

Location/Item

Action

Remarks

CLEANING/INSPECTION OF CAM

FOLLOWERS

CAUTION

Do not wash cam followers with diesel fuel because, at startup,

equipment damage may occur due to lack of lubrication.

20. Cam

Wash with MIL-L-2104 oil and wipe dry.

followers

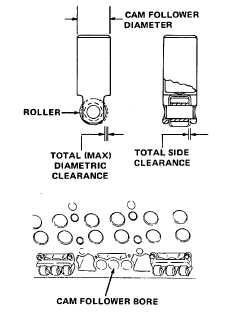

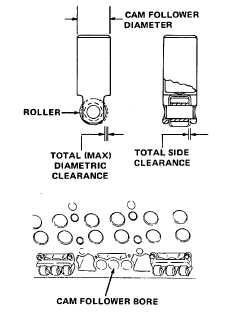

21. Cam

Inspect rollers for scoring,

follower

pitting, and flat spots.

rollers

Rollers must turn freely on

their pins. Measure total

diametric clearance and

side clearance. Diametric

clearance should not exceed

0.010 inch (0.254 mm).

Side clearance should be

within 0.011 to 0.023 inch

(0.279 to 0.584 mm).

22. Cam

Measure diameter of bores and

follower

cam followers. Record the

and bore

readings.

measurement

23. Cam

Subtract diameter of cam follower from inside

follower

diameter of cam follower bore. The difference

and bore

should be between 0.0016 and 0.0036 inch

differential

(0.0406 and 0.0914 mm).

24. Cam

Examine springs for wear or damage and check

follower

the spring load. Springs should not compress

springs

below 2.1406 inches (54.371 mm) while sup-

porting a load of 250 pounds (113.4 kg).

6-33