TM 10-4930-236-13&P

WARNING

When using compressed air, wear safety goggles or glasses and

ensure air blast is not directed at another

person. Do not direct compressed air against the skin.

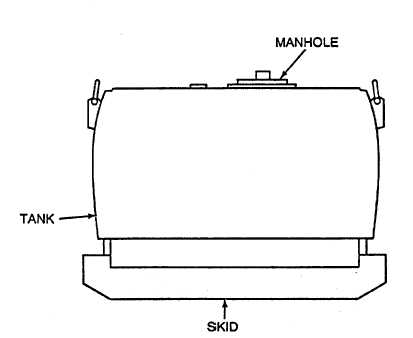

(4) When testing tank, completely dry and clean the interior and exterior of the tank of all foreign matter. When the

tank is completely dry and clean, close all openings such as valves and fill cap, plug and fill cap vent, and subject the

tank to a constant internal air pressure of 3 to 5 pounds per square inch gage (PSIG).Apply liquid detergent conforming

to P-D-223 over the entire exterior surface of the tank at a pressure of not less than 70 PSIG (hand sprayer). Applying

the liquid detergent by brush or other means is not acceptable. Observe the exterior of the tank. Leaks as evidenced by

fizzing or bubbling of the liquid detergent, surface rupture, deformation, or broken hardware shall constitute failure.

f.

Repair of the Tank Assembly.

WARNING

Applying heat or flame to a fuel tank containing residue may

result in a violent explosion, causing injury or death to

personnel. lf conditions require fuel tank repairs by welding or

other methods involving heat or flame, take care to assure that

all fumes are purged from the tank or fill tank with water before

commencing the repair. If possible, tank should be filled with

water prior to welding after being thoroughly purged of fumes.

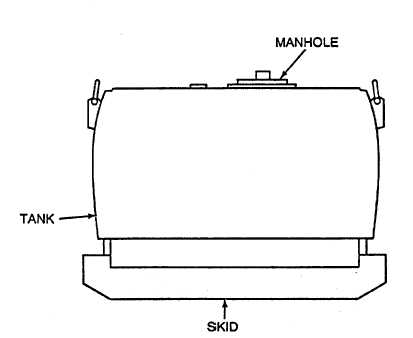

(1) Repair all dents, cracks, breaks,

and holes in the tank. Weld ruptured weld seams

and other damage. Replace badly damaged parts.

Refer to TM 9-237.

(2) if welding repairs are required near

the bottom loading valve, refer to Paragraph 5-8 to

remove the bottom loading valve.

(3) Treat and paint the exterior of the

tank in accordance with TM 43-0139.

5-18