TM 10-4320-344-24

4.4.3 Cylinder Maintenance, Models 609-C and US636HCCD-1.

(Continued)

d .

Remove shims (4) and O-ring seal, if present, from cylinder (2).

Record

thickness of shims (4) and discard O-ring seal.

e .

Place two blocks under piston (1).

4.4.3.2 Repair.

To prevent malfunction of parts,

b e i n g i n s t a l l e d.

piston must be replaced if new cylinder is

a.

Inspect walls of cylinder (2) for scratches or other damage.

b.

Check machined mating surfaces at top and bottom of cylinder (2).

I f s u r f a ce

is not flat or is damaged, replace cylinder (2).

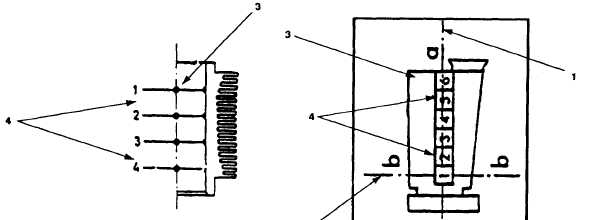

Figure 4-7.

Cylinder Measurement Locations, Models 609-C and US636HCCD-1.

Measurements at all four levels must be made along center line “a” (Figure 4-

7, 1) and cross-line “b” (2).

c .

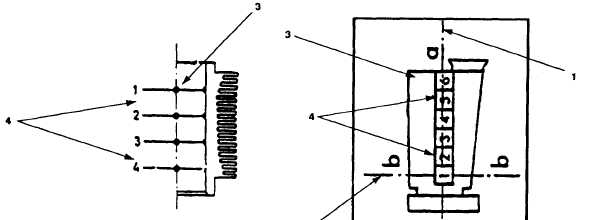

Measure cylinder bore (3) of cylinder (Figure 4-6, 2) at depth levels 1, 2, 3,

and 4, (Figure 4-7, 4).

d .

Replace cylinder if any measurement exceeds 4.0217 inches (102.150 mm) for

Model 609-c and 3.9418 inches (100.122 mm) for Model US636HCCD-1.

e .

Inspect cylinder mating surface on crankcase (Figure 4-6, 3) for scratches or

b u r r s.

4-16