TM 10-4320-344-24

3.8.14 Oil Pump Assembly Maintenance. Model 609-A.

This task covers:

3.8.14.1 Removal

3 .

8 .1 4 . 2 I n s t a l l a t i on

INITIAL SETUP

Tools

Equipment Conditions

General Mechanic’s Automotive

Tachometer Shaft and Angle Drive removed,

Tool Kit, Appendix B, Section III,

paragraph 2.21.45.

Item 1

Oil pan removed, paragraph 3.8.12.

Torque Wrench, Appendix B, Section

III, Item 2

General Safety Instructions

Material/Parts

Do not work on equipment without follow-

ing standard shop safety practices.

Rags, Appendix C, Item 20

Lock Washers (TM 10-4320-344-24P)

3.8.14.1 Removal.

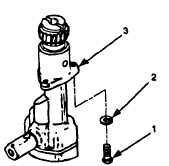

Figure 3-32.

Oil Pump Assembly, Model 609-A.

a.

Turn crankshaft so no. 1, 4, or 6 piston is at TDC.

b.

Remove two bolts (Figure 3-31,

1) and lock washers (2) that secure flange of

oil pump assembly (3) to cylinder block.

Discard lock washers (2).

c .

Rotate crankshaft and, at the same time, remove oil pump assembly (3) with

spiral motion.

3.8.14.2 Installation.

a.

Turn engine crankshaft so no. 1, 4, or 6 piston is at TDC.

b .

Rotate crankshaft and, at the same time,

install oil pump assembly (3) with

spiral motion.

Ensure arrow on oil pump gear is aligned with arrow on fuel

pump attaching pad.

c .

Install two new lock washers (2) and bolts (1) securing oil pump assembly (3)

to cylinder block.

Torque bolts (1) to 25 ft-lbs (34 N•m).

3-77