e .

f .

g .

h.

i .

j .

k.

l .

m.

n.

o .

p .

TM 10-4320-344-24

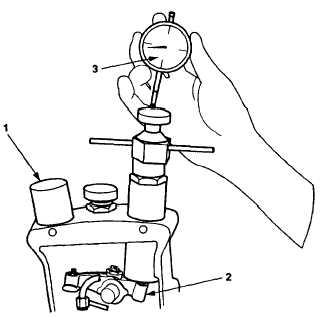

Install injection pump tester (3) on number 1 outlet port of FIP assembly (1).

Do not tighten injection pump tester (3) at this time.

Install pump lever tool (4) under number 1 tappet

Pump the lever on the fuel transfer pump assembly

with pump lever tool (4).

Continue pumping until

outlet port is free of air bubbles.

Tighten injection pump tester (3).

pump lever on fuel transfer pump assembly (5) and

spring in FIP assembly (1).

(5) and pump number 1 tappet

fuel flowing from number 1

pump lever tool (4) on

number 1 tappet until injection pump tester (3) reads 2,175 psi (1,492 kPa) .

Stop pumping.

If pressure on injection pump tester (3) falls more than 145

psi (1,013 kPa) in 1 minute, FIP assembly (1) is defective.

Pump lever on fuel transfer pump assembly (5) and pump lever tool (4) on

number 1 tappet until injection pump tester (3) reads 5,075 psi (34,442 kPa) .

Stop pumping.

If 5,075 psi (34,442 kPa) can not be obtained, FIP assembly (1)

i s d e f e c t i v e.

Release pressure from injection pump tester (3).

Remove pump lever tool (4) and injection pump tester (3) from FIP assembly

( 1 ).

Uncap and connect fuel injection line to number 1 outlet port on FIP assembly

( 1 ) .

Repeat steps d through m until fuel outlet ports 2 through 6 on FIP assembly

(1) have been tested.

Position gasket and cover on FIP assembly (1) in location a and secure with

two washers and screws.

Remove pan and properly dispose of fuel in accordance with standing operating

procedures.

3.8.11.2 Start-of-Delivery Test.

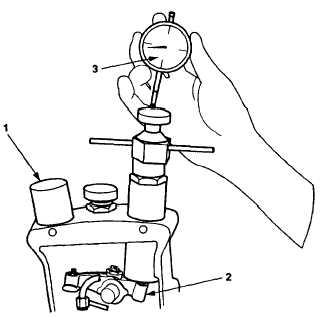

Figure 3-26.

Dial Indicator and Setting Device Installation.

3-67