3.6.7 Impeller Maintenance. (Continued)

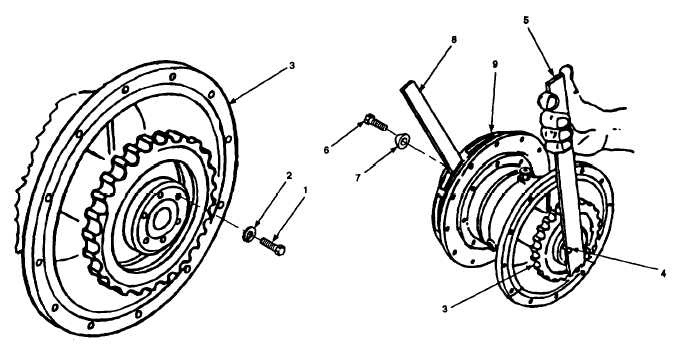

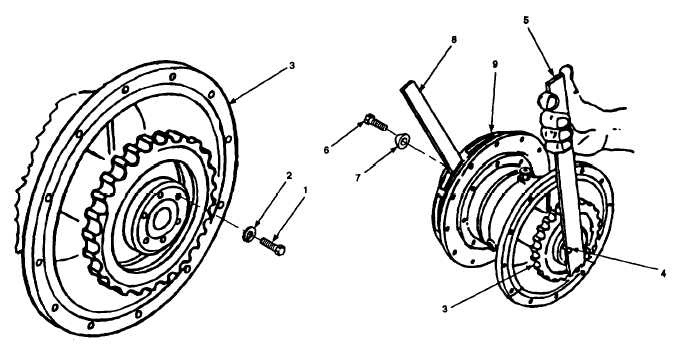

Figure 3-8. Loosening Impeller.

Ensure that steel bar is held rigid while striking with hammer. Impeller is

made of brass and damage to vanes may occur.

Failure to obey this caution

may cause damage to impeller.

f .

While holding steel bar (5) at flexible coupling assembly (3) securely in

position, and steel bar (8) in impeller (9) rigid, firmly strike steel bar (8)

in counterclockwise direction while facing impeller (9) until impeller (9)

unscrews.

g .

Remove steel bars (5 and 8). impeller (Figure 3-9, 1), shims (2), if Present,

seal washer (3), spring (4) seal assembly

impeller shaft (7).

Discard seal assembly

3.6.7.2 Repair.

(5), and stationary seat (6) from

( 5 ).

Do not use cleaning solvent without proper ventilation and clothing.

Do not

smoke or use near open flame or excessive heat.

Dry cleaning solvent is

potentially dangerous to personnel and property.

Clean parts in a well-

ventilated area.

Avoid inhalation of solvent fumes.

Wear goggles and rubber

gloves to protect eyes and skin.

Wash exposed skin thoroughly.

Failure to

obey this warning may result in personal injury or death.

a .

Using cloth soaked in cleaning solvent, clean impeller shaft (7), bore of seal

retaining plate (8), and sleeve spacer (Figure 3-8, 7).

Allow all components

to thoroughly air dry.

3-24

TM 10-4320-344-24