TM 10-4320-344-24

2.23.2 Hub and Wheel Bearing Maintenance.

This task covers:

2.23.2.1

Removal

2.23.2.3

Service

2.23.2.2

Repair

2.23.2.4 Installation

INITIAL SETUP

Tools

Materials/Parts (Continued)

General Mechanic’s Automotive

Cotter Pins (TM 10-4320-344-24P)

Tool Kit, Appendix B, Section

Seals (TM 10-4320-344-24P)

III, Item 1

Bearing Packer, Appendix B, Section

III, Item 2

Goggles, Appendix B, Section III,

Equipment Conditions

Pumping Station shut down, TM 10-4320-

344-10.

Wheel Assembly removed, paragraph 2.23.1.

Material/Parts

General Safety Instructions

Gloves, Appendix C, Item 11

Do not work on equipment that is not

Grease, Appendix C, Item 12

securely stabilized to prevent rolling or

Rags, Appendix C, Item 20

sliding.

Solvent, Dry Cleaning, Appendix C,

Item 26

Do not work on equipment without fol-

lowing standard shop safety precautions.

This procedure applies to Model 609-C. The procedures for Models 609-A and

US636HCCD-1 are similar.

2.23.2.1 Removal.

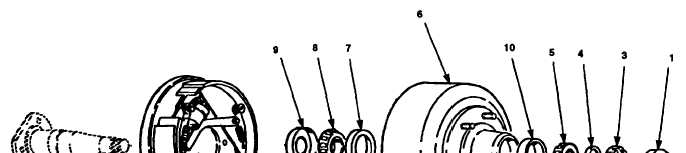

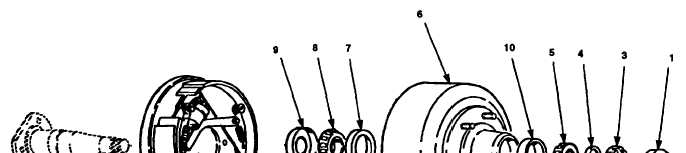

Figure 2-169. Hub and Wheel Bearing Maintenance.

a.

Remove grease cap (Figure 2-169, 1), cotter pin (2), castle nut (3), and

washer (4) . Discard cotter pin (2).

NOTE

2-379

Item 2