Table 2-11.

Preventive Maintenance Checks and Services for Pumping Assembly

Model 609-C.

(Continued)

Location

Item

Item to

Not Fully Mis-

No.

Interval

Check/Service

Procedure

sion Capable if:

34

35

To prevent fire or explosion and possible personal injury, keep open flame

sparks away from fuel tank.

A f t er

A f t er

To prevent condensation, fill tank after operation.

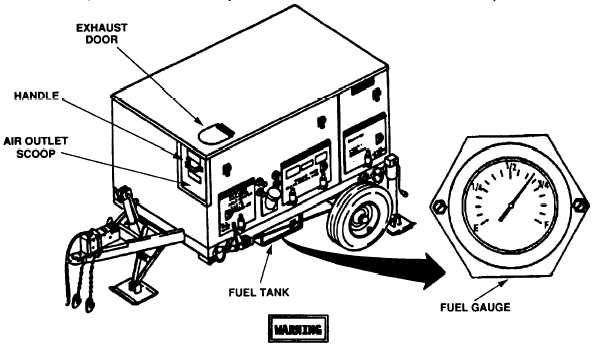

Fuel Tank

Gauge

and

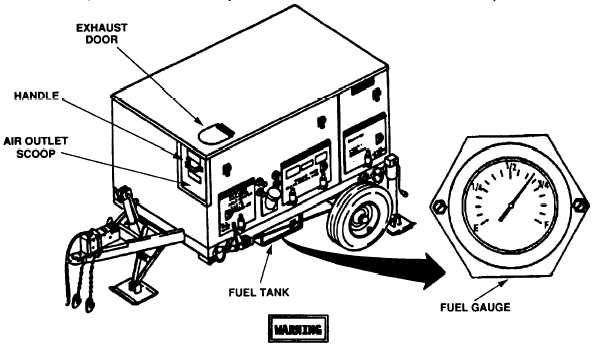

Cooling Air/

Engine Exhaust

Check fuel tank for cracks,

damage, and leaks.

Check fuel

level indication on fuel gauge.

If fuel is required, remove

fuel tank cap and add fuel.

Install cap after adding fuel.

Pull air outlet scoop handle

outward and check that cooling

air outlet scoop and engine

exhaust door open with moderate

pull on handle.

Check for

deformation and missing

hardware.

Push handle inward

and check that both exhaust

door and outlet scoop close

e a s i l y .

If hardware is missing

or scoop or door is loose,

deformed, or hard to operate,

notify unit maintenance.

and

C l a s s I , I I , or

III leak.

Cracked or

damaged fuel

tank.

Outlet scoop or

exhaust door is

loose, deformed,

or inoperable.

Hardware is

missing.

2-55

TM 10-4320-344-10