Table 2-11.

Item

No.

23

24

25

Interval

Before

During

Preventive Maintenance Checks and Services for Pumping Assembly

Model 609-C.

(Continued)

Location

Item to

Check/Service

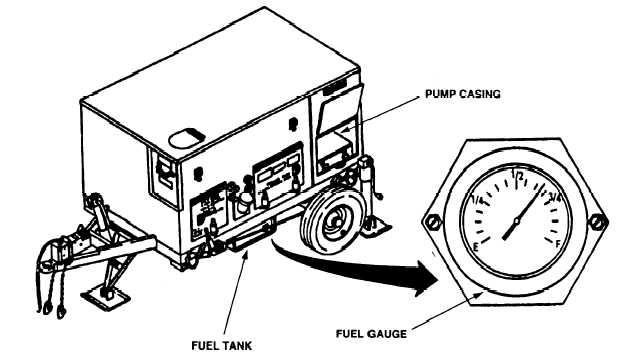

PUMP ASSEMBLY

Pump Casing

EXTERIOR

Leaks

FUEL TANK

Procedure

Check for damage or leaks. If

pump is damaged, notify unit

maintenance

Inspect ground under engine for

evidence of leaks.

If leaks

are present, notify unit

maintenance.

Not Fully Mis-

sion Capable if:

Class III leak.

pump is damaged.

Any evidence

leaks.

o f

Hot refueling of pumping assembly while it is operating poses a safety hazard

and should not be attempted.

Hot engine surfaces and sparks produced from the

engine and control circuitry are possible sources of ignition.

Severe

personal injury or death and/or damage to the equipment may result.

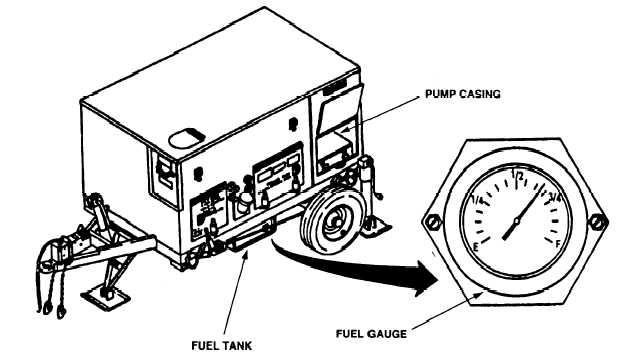

During

Fuel Tank and

Gauge

Check fuel tank for cracks,

damage, or leaks.

Check fuel

level indication on fuel gauge.

If fuel is required, stop

engine and allow to cool.

Then

remove fuel tank cap and add

f u e l.

Install cap after adding

—

f u e l.

C l a s s I , I I , or

I I I l e a k.

Cracked or

damaged fuel

tank.

2-51

TM 10-4320-344-10